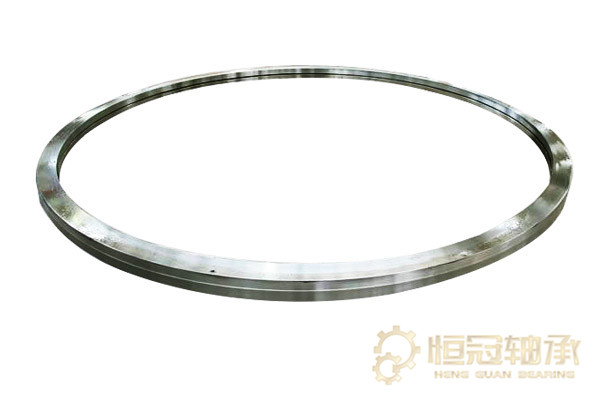

Large Thrust Ball Turntable Bearing

- LYHGB

- LUOYANG

- 45 DAYS

- 4000 SETS/ MONTH

Large thrust ball bearings are composed of three parts: seat ring, shaft ring and steel ball cage assembly. The shaft ring is matched with the shaft and the seat ring is matched with the housing. Because it is more suitable for bearing axial load but not radial load, and the limit speed is low, the large thrust ball bearing is suitable for parts bearing one side axial load and low speed, such as crane hook, vertical water pump, Vertical centrifuges, jacks, low speed reducers, etc.

Characteristics of large thrust ball bearings:

1.Using ultra-clean steel that can prolong the service life of large thrust ball bearings.

2. When selecting the type of large thrust ball bearing, in order to allow installation error, the spherical self-aligning spherical seat cushion type or the spherical seat ring type can be selected.

3. High lubrication technology, NSK's lubricant technology can prolong the life of grease and improve the performance of large thrust ball bearings.

4. The steel ball is of high quality, which can make the large thrust ball bearing rotate quietly and smoothly.

Large thrust ball bearings

Large thrust ball bearings are composed of three parts: seat ring, shaft ring and steel ball cage assembly. The shaft ring is matched with the shaft and the seat ring is matched with the housing. Because it is more suitable for bearing axial load but not radial load, and the limit speed is low, the large thrust ball bearing is suitable for parts bearing one side axial load and low speed, such as crane hook, vertical water pump, Vertical centrifuges, jacks, low speed reducers, etc.

Characteristics of large thrust ball bearings

1.Using ultra-clean steel that can prolong the service life of large thrust ball bearings.

2. When selecting the type of large thrust ball bearing, in order to allow installation error, the spherical self-aligning spherical seat cushion type or the spherical seat ring type can be selected.

3. High lubrication technology, NSK's lubricant technology can prolong the life of grease and improve the performance of large thrust ball bearings.

4. The steel ball is of high quality, which can make the large thrust ball bearing rotate quietly and smoothly.

Precautions for the use of large thrust ball bearings

1. Special tools should be used for installation tools, and the use of cloth and short fibers should be avoided.

2. Keep the large thrust ball bearing and the surrounding environment clean to avoid dust entering the bearing and causing bearing wear.

3. It is not allowed to use a hammer to hit the large thrust ball bearing, and there should be no strong stamping.

4. In order to prevent the large thrust ball bearing from rusting, clean or wear a mask when touching it with hands.

Reasons and solutions for damage to large thrust ball bearings

1. Improper lubrication. One of the reasons for the damage of large thrust ball bearings is that the lubricating oil is not filled in time, the oil is improperly selected, and the lubrication method is improper.

Solution: Select the correct lubricating oil and the correct lubrication filling method according to different bearing models. When lubricating instruments or high-speed bearings, clean oil is generally used to remove the rust inhibitor of the bearing, and then lubricate. If you have any questions about the choice of lubricating oil, you can also leave a message to consult our Hengguan Bearings.

2. Bearing contamination. The reasons for the contamination of large thrust ball bearings include premature opening of the package, contamination of the installation environment, entry of dust, etc. into the inside of the bearing, increasing bearing wear and causing noise and vibration during the operation of the bearing.

Solution: Do not unpack before use, keep the installation and operating environment of large thrust ball bearings clean, keep hands clean when operating by hand, pay attention to rust prevention, and clean large thrust ball bearings regularly.

3. Overload. The overload of the bearing includes running the bearing with overload for a long time, not regularly maintaining the large thrust ball bearing, and not protecting the equipment after the shutdown.

Solution: Regularly maintain and maintain the bearing, pay attention to the load condition to avoid bearing overload, choose professional maintenance, and cover the machine with oil paper and other materials after the equipment is stopped.

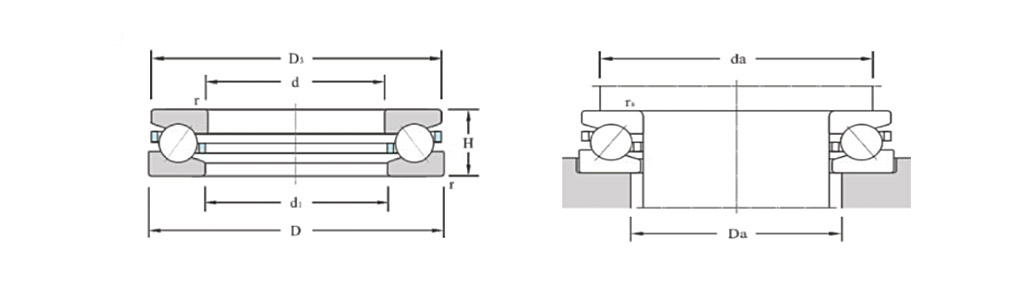

| Bearing code | Dimensions | Rated load | Limited speed | Small load constant | Weight | |||||||||

| Current model | Original model | d | d1 | D | D3 | H | rmin | a | Dynamic load C | Static load Co | Grease | kg | ||

| mm | KN | r/min | A | |||||||||||

| 5617/650 | 1687/650 | 650 | 720 | 880 | 800 | 140 | 6 | 60° | 1105 | 7692 | 260 | 370 | 7.092 | 194 |

| 5692/670 | 91682/670 | 670 | 740 | 900 | 830 | 140 | 6 | 45° | 1260 | 6084 | 250 | 360 | 53 | 206 |

| 5691/750 | 91681/750 | 750 | 780 | 900 | 870 | 90 | 4 | 60° | 587 | 4620 | 340 | 480 | 40 | 94.4 |

| 5611/800 | 1681/800 | 800 | 840 | 950 | 910 | 120 | 4 | 60° | 850 | 6710 | 200 | 240 | 6.71 | 140 |

| 5692/800 | 91682/800 | 870 | 1060 | 990 | 155 | 7.5 | 60° | 1145 | 8868 | 180 | 250 | 150 | 293 | |

| 5617/810 | 1687/810 | 810 | 880 | 1030 | 960 | 110 | 7.5 | 45° | 780 | 4080 | 280 | 400 | 150 | 176 |

| 5691/950 | 91682/950 | 950 | 1040 | 1250 | 1160 | 180 | 7.5 | 45° | 1500 | 9168 | 120 | 170 | 60 | 432 |

| 5691/1000 | 91681/1000 | 1000 | 1040 | 1180 | 1140 | 109 | 5 | 45° | 1076 | 6516 | 250 | 360 | 200 | 177 |

| 5691/1120 | 91681/1120 | 1120 | 1170 | 1320 | 1270 | 122 | 5 | 60° | 1018 | 10272 | 180 | 260 | 10.272 | 241 |

| 5617/1270 | 1687/1270X | 1270 | 1290 | 1430 | 1410 | 110 | 4.5 | 60° | 1100 | 10859 | 170 | 250 | 210 | |

| 5617/1600 | 1687/1600 | 1600 | 1600 | 1760 | 1760 | 90 | 6 | 60° | 682 | 8052 | 210 | 300 | 8.052 | 248 |

| 5617/1860 | 1687/1860 | 1860 | 1900 | 2100 | 2060 | 140 | 4.5 | 60° | 1272 | 19370 | 93 | 130 | 19.07 | 577 |

| 5617/2100 | 1687/2100 | 2100 | 2120 | 2280 | 2260 | 150 | 4.5 | 60° | 1200 | 19300 | 78 | 111 | 19 | 563 |

| 5610/2500 | 11689/2500 | 2500 | 2520 | 2700 | 2680 | 160 | 5 | 60° | 1584 | 26640 | 57 | 81 | 26.64 | 732 |

| 5617/2530V/HG2 | 2530 | 2564 | 2650 | 2624 | 75 | 4 | 60° | 954 | 7500 | 50 | 80 | 174 | ||

| 5617/3000/YA | 1687/3000 | 3000 | 3000 | 3270 | 3270 | 140 | 7.5 | 60° | 1464 | 24240 | 52 | 75 | 24.24 | 1262 |