Cause analysis of fracture phenomenon of slewing ring bearing

Cause analysis of fracture phenomenon of slewing ring bearing

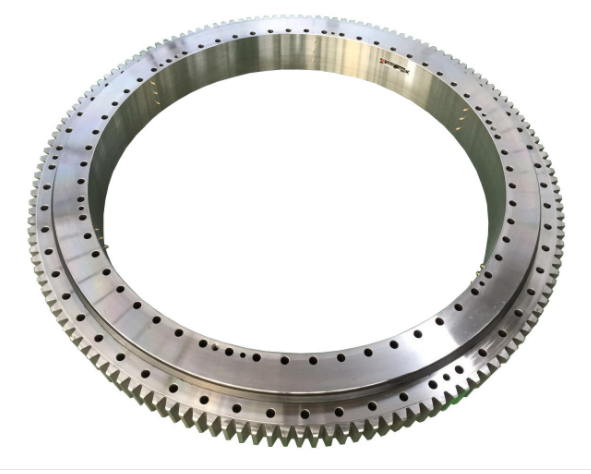

During the use of construction machinery and equipment, various problems cannot be avoided. Sometimes the slewing bearing suddenly breaks, which will not only affect the production progress, but also cause huge losses and may be dangerous. What is the reason? Today, Hengguan Bearing will analyze with you the reasons for the fracture of the slewing ring bearing.

The reason for the breakage of the slewing bearing

1. Material issues

The fracture of the slewing bearing can be said to be a major quality problem of this part. The fracture of the slewing bearing refers to the failure of the inner and outer rings of this type of bearing. The main reason is that the tensile strength, yield strength and impact toughness of the material are not up to the standard. The mechanical properties of the material from which this type of bearing is made. The main material of the slewing bearing is carbon structural steel, and 50Mn and 42CrMo are commonly used materials in this industry. 50Mn mechanical properties: (1) Tensile strength σb (MPa): ≥645(66); (2) Yield strength σs (MPa): ≥390(40); (3) Elongation δ5 (%): ≥13 ; (4) Reduction of area ψ (%): ≥40; (5) Impact energy Akv (J): ≥31; (6) Impact toughness value αkv (J/cm2): ≥39 (4). When the slewing bearing works under normal operating temperature (-30°C to 70°C) but breaks, the basic problem is material problem.

2. Processing heat treatment

The production and processing process requires heat treatment of the raceway. If the heat treatment fails, the surface hardness is low. The hardness layer penetrates into the structure of the slewing bearing or reaches the wall of the slewing bearing, which changes the mechanical properties of the material of the inner and outer rings of the slewing bearing. The overall tensile strength and impact toughness of the material becomes smaller, the material becomes brittle.

3. Design structural issues

Due to the design structure of the slewing bearing, after heat treatment, the quenched layer is equal to the design thickness of the inner and outer rings. At this time, the tensile strength and impact toughness of the material are small, resulting in fracture. However, this possibility does not account for a high proportion of fracture accidents.

There are many reasons for the breakage of turntable bearings. When substandard ring forgings are used, the material quality of the selected bearings may cause fracture. When selecting turntable bearings, we must choose a good single row cross roller turntable bearing manufacturers, so that the material and design and processing of the bearings can be guaranteed.