Selection and Application of Slewing Bearing of Pile Puller

Selection and Application of Slewing Bearing of Pile Puller

Pile extractor is a kind of piling machine that uses vibration, static force or hammering to pull piles out of the ground. The corresponding vibratory pile driver, static pile driver or double acting steam hammer are often used for pile pulling operation, together with pile frame and rigging, so they are also known as vibratory pile driver and static pile driver. The use of slewing bearing on pile extractor is still the force transmission element of upper body and lower body in relative rotary motion, so how to select and use it? Let's introduce it to you.

1.Selection of slewing bearing of pile extractor

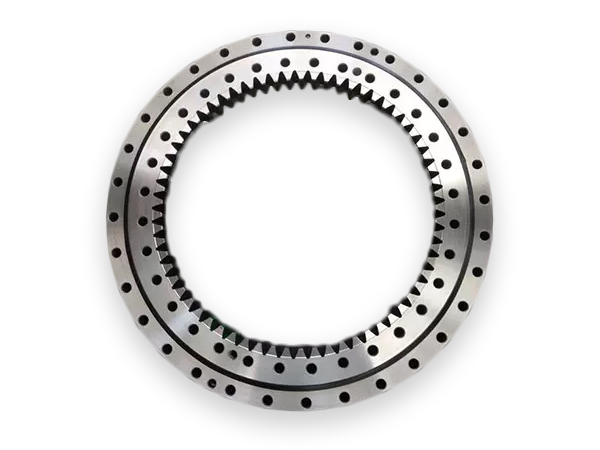

The slewing ring of the pile extractor realizes the rotation of the device through friction and lubrication. In the pile extractor, it can drive the machine to rotate and provide support capacity. It mainly plays the role of rotation and support. It should bear axial, radial, overturning and impact loads. Because of the high quality requirements for the slewing ring, the double volleyball slewing ring is generally selected when selecting the type of slewing ring. This type of slewing ring has a tight structure It can withstand large axial force and tipping moment.

2. Use method of slewing bearing of pile extractor

The slewing bearing of the pile extractor is similar to the use method of the pile driver and excavator. The slewing bearing is a force transfer element for the upper body and the lower body to make relative rotary motion, which is used to support the weight of the upper body and bear the working load. The inner race is connected to the lower car body, the outer race is connected to the upper car body, and the inner gear ring on the inner race is engaged with the pinion of the swing motor. When the swing motor rotates, it drives the upper body to rotate through the pinion. The slewing ring of the pile extractor uses an internal tooth type slewing ring. Because of the impact load, the tooth surface is generally quenched.

Vibratory pile extractors are common in construction. During operation, the vibratory pile extractor is fixed on the pile head, suspended under the hook through the spring vibration absorber and rigging. When the pile extractor is started, the vibration generated by the vibrator will cause resonance between the pile and the soil, damage the soil structure, reduce the friction between the pile and the soil, and tighten the rigging to gradually pull out the pile. If eccentric block vibrator is used, the eccentric block must be adjusted due to the different resistance directions of pile sinking and pile pulling. This kind of pile pulling equipment has simple structure, high pile pulling efficiency and a promising future.

The hydraulic pile extractor uses its pile gripper to clamp the pile head, and the hydraulic cylinder forces the pile gripper to jack it up for a certain distance to pull out the pile section by section. It is suitable for pulling I-steel or section steel piles in clay, sandy soil or soil layer containing a small amount of gravel. There are also those who use mechanical methods to pull the pile, that is, the motor drives the winch to forcibly pull the pile out of the ground by using the tension of the wire rope pulley block. It is convenient to use and low in cost, but the pile pulling force is not large, the equipment is heavy, and the pile pulling efficiency is low, so it is only applicable to the construction of soft soil layer. The double acting steam hammer is used to pull out the pile. The hammer body is inverted, fixed on the pile head, and suspended under the rigging. First shake the pile head in the soil to reduce the density between the pile and the soil, then start the steam hammer, hammer upward to vibrate, tighten the rigging, gradually pull out the pile, and pull out the concrete pile and other piles in various soil layers.

In general, the pile extractor is a large mechanical equipment. Like the excavator and crane, it will produce large working load and friction during rotation. Ordinary bearings cannot meet the needs of large mechanical equipment, so slewing bearings are required. When selecting models, they should be customized according to the actual situation. Some places with severe wear can be treated with special processes to increase the quality of slewing bearings.