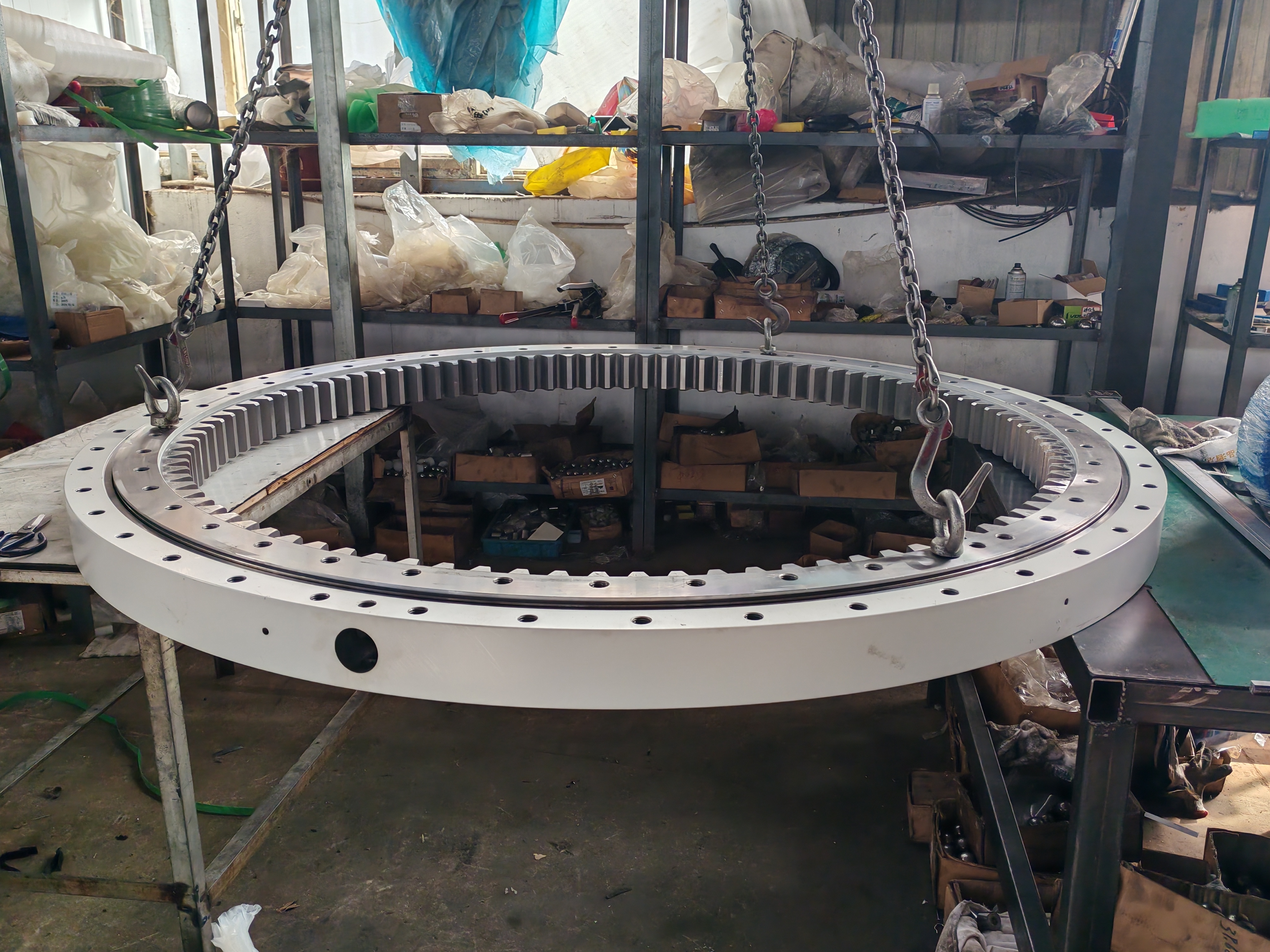

Do you know all the knowledge points of these slewing bearings?

Today, the editor has collected some relevant information about slewing bearings for everyone. Friends who are interested in this, hurry up and learn about it!

1.The types of slewing brackets include four-point contact ball bearings, self-aligning bearings, angular contact ball bearings, cross cylindrical roller bearings, cross tapered roller bearings and three-row cylindrical roller bearings.

2. The characteristics of various specifications and models of slewing brackets

(1) Single and double row steel ball slewing brackets, single and double row steel ball slewing brackets, one row of steel balls as the turning body, there are separate protective blocks between the steel balls, the inner and outer rings of the steel balls are integral, and the steel balls are loaded into the steel balls according to the insertion holes.

(2) The double-row four-point contact ball rotating support structure is similar to the single-net ball rotating support structure. The difference is that two rows of steel balls are used as the rotating body. The specifications of the two rows of steel balls are the same. A separate protective block is set between the steel balls. The inner and outer rings are integral. The steel balls are loaded into the steel balls through the insertion holes. This requires the server to have faster products and the tangential structure specifications are relatively limited. The four-point contact ball bearing has a higher static load test capacity.

(3) Three-column rotating support, the three-column rotating support is a rotating support with higher load-bearing capacity. It is suitable for large outer diameter operations. It consists of three rings. The left and right rows of rollers are horizontally distributed. The bearing capacity and tilting torque, the tangential force is borne by the vertically arranged third row of rollers. It is the choice of large and medium-sized rotating supports with a diameter of more than 1800mm.

(4) The cross roller slewing bearing is similar to the single and double row steel ball slewing bearing. It has only one row of rollers. The roller body is a cylindrical roller. The direction of adjacent rollers is 90° cross-separated. The inner and outer rings each have two raceways. The cross section of the raceways is parallel. Half of the rollers bear the downward force.

(5) The double row steel ball slewing bearing consists of left and right double rows of steel balls, inner and outer rings, protective blocks and smooth sealing devices, but the double rows are different.

3. Characteristics of the diameter column four-point contact slewing bearing Column four-point contact slewing bearing, this type of rolling bearing consists of two steel rings, steel balls and curved rails in four-point contact. It can bear axial force, tangential force and tilting torque at the same time. It has the characteristics of compact structure, light weight, high precision and strong bearing capacity. Common excavators, pile drivers or lifting equipment, military equipment and other industries. The independent variables and fitness movements are mainly transmitted by the point contact between the inner and outer wheels and the rotating body. Due to the large transmission offset and small contact area, the stress in the contact area is increased.

4. Key components Steel ring: S48C, 42CrMo4 and other materials Steel ball: 45# steel, such as GCr4, GCr9, GCr15SUJ2, etc.