Excavator slewing bearing structure, principle, failure causes and detection methods

The excavator can rotate left and right during work and cannot do without the slewing device. The slewing bearing is an important part of the slewing mechanism. The slewing bearing of the excavator is mainly used to support the mass of the upper body and bear the working load. This component is also the place where the excavator is prone to failure. This article mainly introduces the slewing bearing, its failure causes and maintenance methods.

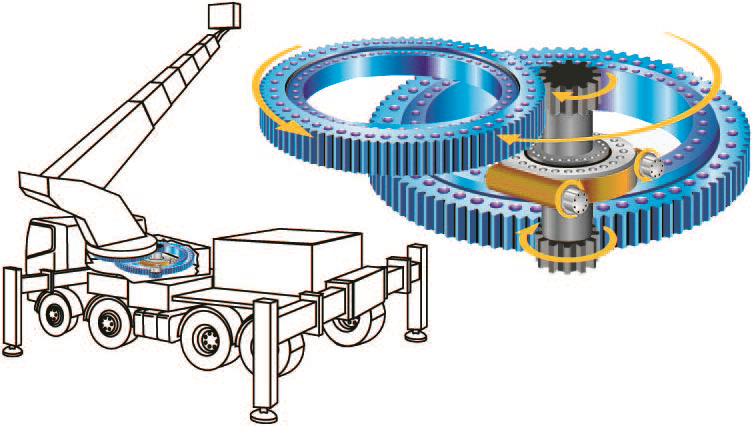

1. Structure and principle of slewing bearing

(1) Structure

The slewing bearing of the excavator is a force transmission element for the relative rotation between the upper body and the lower body. It is used to support the mass of the upper body and bear the working load. The inner race is connected to the lower body, the outer race is connected to the upper body, and the internal ring gear on the inner race is meshed with the pinion of the rotary motor. When the rotary motor rotates, the pinion drives the upper car body to rotate.

(2)Principle

Lubrication: The slewing bearing of the excavator is lubricated with grease. The lubrication is divided into two parts, namely the lubrication part of the inner cavity of the slewing bearing (rolling elements and raceways), and the lubrication part of the internal ring gear and the pinion of the slewing motor. The inner cavity of the slewing bearing is lubricated with grease through the grease nozzle located on its outer race. The internal ring gear of the slewing bearing and the pinion gear of the slewing motor are lubricated by pre-added grease.

Sealing: The slewing bearing has two oil seals, inner and outer. The outer oil seal is fixed on the lower part of the outer surface of the inner seat ring. Its main function is to prevent dust from entering the inner cavity of the slewing bearing. The inner oil seal is located on the upper part of the inner circle of the outer race of the slewing bearing. Its main function is to prevent the grease in the inner cavity of the slewing bearing from overflowing. The grease filling cycle for the inner cavity of the slewing bearing should be between 250 and 300 hours. The filling of grease can be completed in 4 times, that is, filling once every 90° rotation of the excavator, and the filling amount is until the grease overflows from the outer oil seal.

2.Fault type

There are two types of faults that are prone to occur in excavator slewing bearings:

First, the slewing bearing of the excavator often operates under heavy loads and heavy impact conditions, and the working environment is harsh, causing the inner and outer oil seals of the slewing bearing to wear quickly, causing grease leakage.

Second, the bottom plate connecting the upper turntable and the slewing bearing was severely deformed under eccentric load conditions, causing the load to concentrate on a small part of the rolling elements, causing damage to the rolling elements, inner race, outer race and slewing motor.

3. Cause of failure

Oil seal wear When the excavator rotates, the outer race and oil seal rotate relative to the inner race, which can cause the inner oil seal to wear and gradually become thinner. When the inner oil seal becomes thinner, its sealing effect decreases. At this time, if too much grease is added to the inner cavity of the slewing bearing or the operating temperature increases, the pressure in the inner cavity of the slewing bearing will increase and the grease will leak from the inner oil seal.

Uneven grease filling If grease is only added to the same part of the inner cavity of the slewing bearing, the grease will be filled unevenly, causing the outer oil seal to be squeezed out and fall off, or a large amount of grease to leak out.

Poor quality of grease If the quality of the grease added is poor, the grease will become thinner when the temperature of the friction part of the slewing bearing increases. The thinned grease will leak out from the outer oil seal.

Slewing bearing wear If the excavator makes abnormal noise during rotation or the rotation is unstable, it may be caused by serious wear of the slewing bearing raceways and rolling elements and excessive clearance between the inner and outer races. During the rotation of the slewing bearing, the grease is squeezed out from the inner and outer oil seals, which can cause damage to the inner and outer oil seals.

4. Fault diagnosis and detection methods

Oil seal fault diagnosis method

Inner oil seal Open the grease inspection cover of the inner ring gear of the slewing bearing and check whether there are broken pieces of the inner oil seal in the oil chamber of the inner ring gear. If there are broken pieces of the inner oil seal in the inner ring gear oil chamber, it indicates that the inner oil seal has been damaged.

Carefully inspect the outer oil seal along the outer oil seal of the slewing bearing to see whether the slewing bearing is leaking locally, in sections or even around the perimeter. At the same time, check whether the mounting grooves on the outer oil seal and the inner seat ring of the slewing bearing are fixed, so as to determine whether the outer oil seal is damage. When checking the outer oil seal, it must be carried out when the excavator is rotating. If the outer oil seal rotates at the same time when the excavator is rotating, it means that the outer oil seal has become loose and needs to be replaced with a new one.