How to extend the service life of slewing bearings

In order to extend the service life of slewing bearings, every aspect of installation, use and maintenance is crucial.

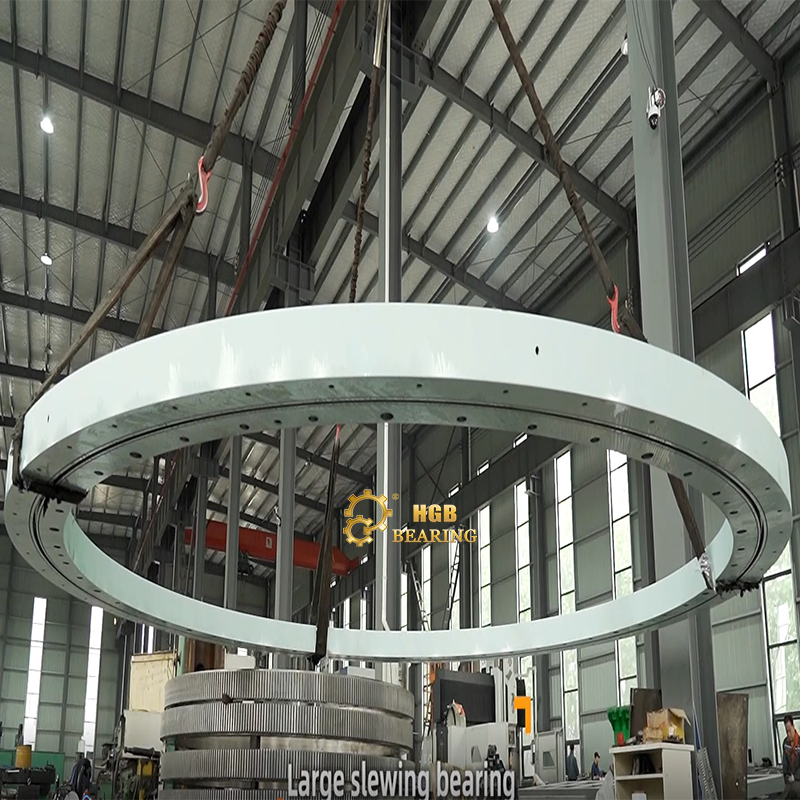

During installation, it is necessary to ensure that the support of the slewing bearing has sufficient rigidity, the installation surface is flat and clean. When hoisting, a balanced and stable method should be used to avoid collisions and impacts that may cause bearing deformation.

shape. When connecting bolts, the pre-tightening force requirements should be strictly followed and the force should be applied gradually in multiple times to ensure the accurate position of the bearing. After the installation is completed, Operation inspection is also required to ensure that the equipment does not make abnormal sounds, excessive temperature rise, or excessive vibration.

During use, you should pay close attention to the changes in noise and rotational resistance torque. Once any abnormality is found, it should be disassembled and inspected immediately. In addition, the slewing bearing must be lifted or stored horizontally, and vertical lifting or storage should be avoided to prevent deformation. Regularly remove debris from the tooth surface and re-apply grease to maintain good lubrication.

In terms of maintenance, key parts such as the raceways and gears of the slewing bearing should be inspected regularly, and problems such as cracks and wear should be discovered and dealt with in a timely manner. At the same time, the fastening of high-strength bolts and nuts and other connecting parts should be checked regularly to prevent loosening.

In short, correct installation, standardized use and regular maintenance are the keys to ensuring long-term stable operation of slewing bearings. Only in this way can its service life be extended to the greatest extent and the overall quality of the equipment improved body performance.