Slewing bearing manufacturers take you to understand the inspection standards of slewing bearings

Slewing bearing manufacturers take you to understand the inspection standards of slewing bearings

After the user purchases the slewing bearing, how to identify the quality of the slewing bearing? What are the inspection standards for slewing bearings? Today, the slewing bearing manufacturer - Luoyang Hengguan Bearing Technology Co., Ltd. will take you to know about our slewing bearing inspection standards.

Generally speaking, the inspection of slewing bearings requires the following 17 inspection standard requirements for slewing bearings:

1. Slewing bearing clearance inspection

Generally, the required axial and radial clearances will be indicated during the design of the slewing bearings. The produced slewing bearings must check the clearance data to see if the data is consistent

with the design drawings. Too large or too small a gap will cause problems, and only the gap that meets the design requirements is the most suitable.

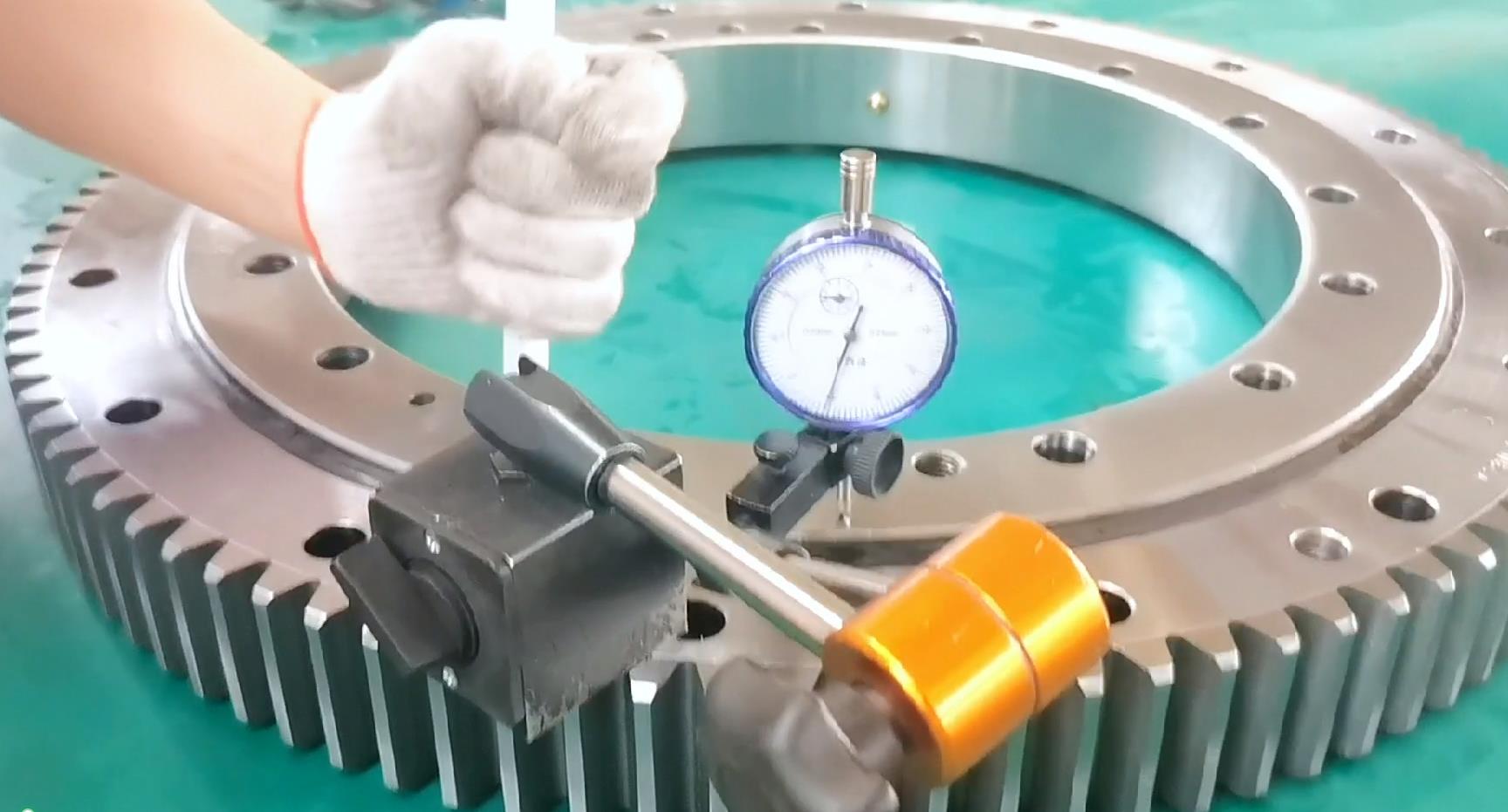

2. Slewing bearing runout inspection

Same as clearance inspection, slewing bearing runout inspection is divided into axial runout inspection and radial runout inspection. Conditional users can use testing equipment to check the runout data of

slewing bearings to check whether they meet product design requirements.

3. Inspection of rotation flexibility of slewing ring

Place the slewing bearing flat on the horizontal workbench, and turn the slewing bearing.

It is basically normal that the slewing bearing can be rotated by general manpower or force. If it feels tight when turning, you can add grease and try again. Pay attention to whether there is abnormal sound

in the slewing bearing during the rotation process. If it is a continuous rolling sound during the rolling of steel balls, it is normal. If there is intermittent and sharp abnormal sound, it needs to be reported to

the slewing bearing manufacturer immediately.

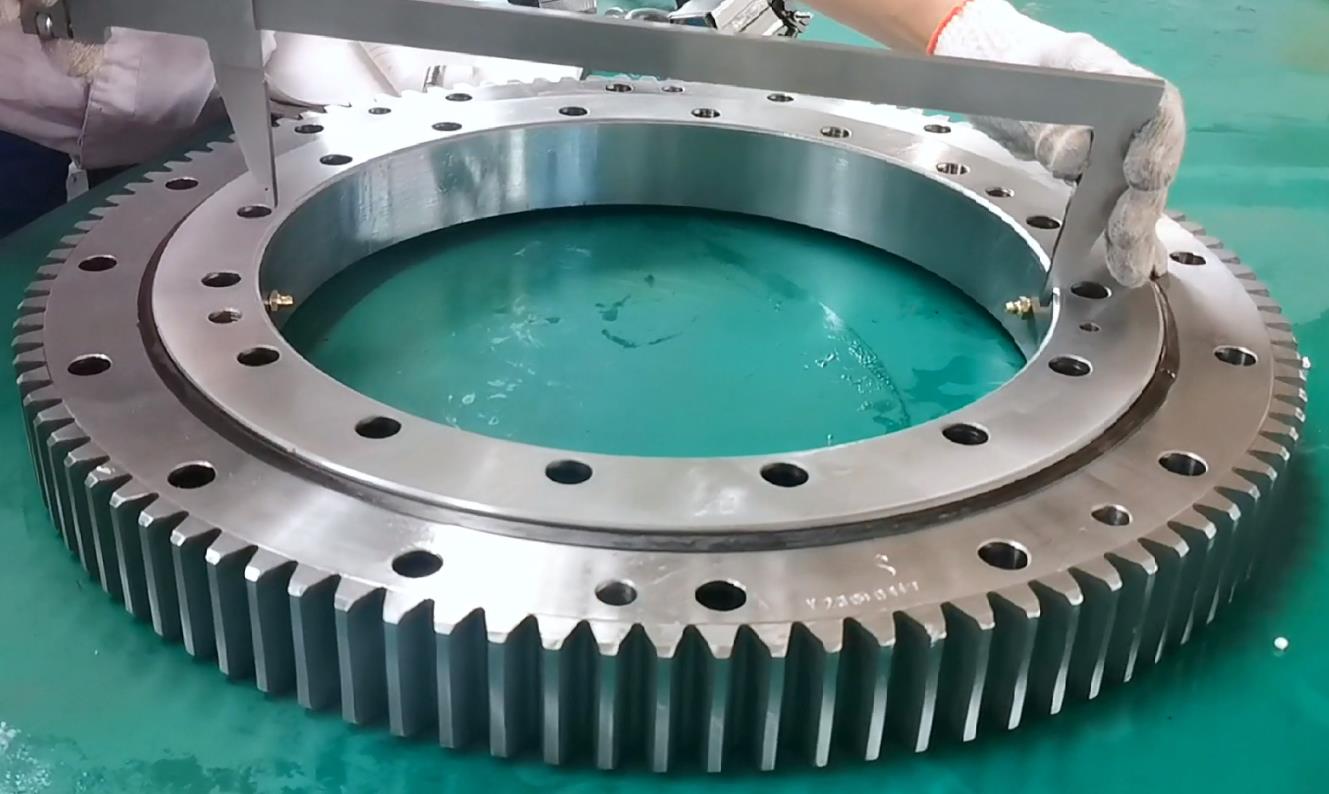

4. Slewing bearing size inspection

Check whether the external dimensions of the slewing bearing conform to the design drawings, including the inner diameter, outer diameter, and thickness of the slewing bearing, and check whether

the external dimension data meet the requirements of the design drawings.

5. Product number and label inspection

Regular manufacturers of slewing bearings will provide slewing bearing product numbers, product labels, and quality certificates to facilitate installation and storage by users.

6. Seal installation inspection

The seal of the slewing bearing needs to be strictly inspected by the user. If the sealing strip is not installed firmly or falls off, foreign matter such as sand and gravel will enter the slewing bearing track,

causing the slewing bearing to fail to rotate or even the track to be damaged. The inspection method is to rotate the slewing bearing to check whether the sealing strip is firmly installed and whether the

bonding is stable.

7. Appearance quality inspection

Although the appearance quality of the slewing bearing does not affect the normal use, it definitely represents the production management quality of a slewing bearing manufacturer. Good and regular

slewing bearing manufacturers have strict slewing bearing production and inspection standards and processes to ensure that each set of slewing bearings meets the best inspection requirements in terms

of appearance and internal quality.

8. Packaging inspection

Before packaging, the slewing bearing needs to be coated with a layer of anti-rust oil, then the first layer is wrapped with a waterproof film, the second layer is wrapped with a packing tape, and the third layer

is wrapped with a waterproof film. Generally, for slewing bearings with special packaging and transportation requirements, custom packaging wooden boxes are also required.

In addition to mastering the above slewing bearing inspection standards, you can also ask the slewing bearing manufacturer to provide the slewing bearing production inspection report.

Generally, regular manufacturers will keep an original slewing bearing inspection report for each slewing bearing to seal the original data of the product. and management. With the inspection report, I believe

you will be more assured of the slewing ring you purchased.