Reasons and treatment methods for oil leakage of slewing bearing

Reasons and treatment methods for oil leakage of slewing bearing

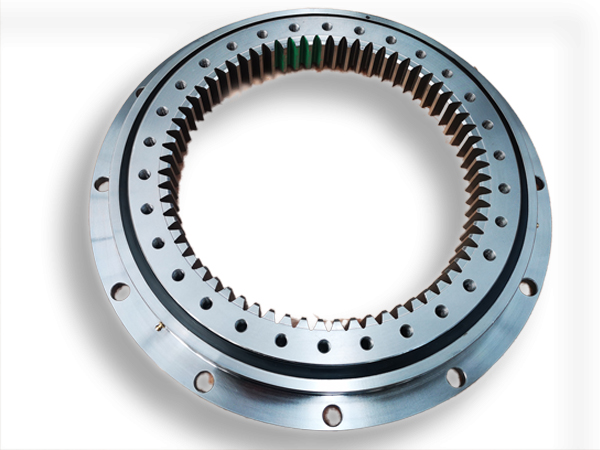

Slewing bearings are used in many large-scale mechanical equipment. With the continuous increase of operating time, some failures will inevitably occur in bearings. For example, oil leakage is one of the common problems. Many friends reported that after the oil leakage of the slewing bearing, the grease remaining on the bearing surface will adhere to a lot of dirt, which is easy to cause corrosion to the bearing, which makes them very distressed and do not know how to deal with it. In order to solve everyone's confusion, we will introduce the causes and treatment methods of oil leakage of slewing bearings.

1. Reasons for oil leakage of slewing bearing

1) Frequent filling of lubricating grease or thinning of grease

The more lubricating oil is filled, the better. The oil filling period of the slewing bearing is generally between 150 and 250 hours, which can be adjusted according to the operating conditions. However, if the filling is too frequent, it will cause grease leakage; The hydraulic oil or gear oil escapes into the cavity of the rotating ring gear, which will dilute the lubricating oil and cause oil leakage.

2) Incorrect selection of grease

Bearings and transmissions have suitable grease types. If unsuitable lubricating oil is added, the grease may become thin due to high temperature during operation, and the thin grease will be affected by the driving gear of the rotary motor. Push down to the upper section of the inner gear ring, and then flow into the bearing cavity through the inner oil seal, and leak from the outer oil seal.

3) Defective or loose outer oil seal

If the rotary oil seal is defective, it will cause partial or section leakage of grease; in addition, the loose oil seal will also cause oil leakage, which can be observed when the equipment is running. If the oil seal and the equipment rotate at the same time, it means that the existing oil seal is in the sealing groove. It has been loose and needs to be replaced in time (be sure to pay attention to safety during inspection).

4) The inner oil seal is damaged or the bearing clearance becomes larger

The damage of the inner oil seal is one of the reasons for the oil leakage of the slewing bearing. You can open the lubricating grease inspection cover of the slewing ring gear to see if there are broken pieces of the oil seal; in addition, if the bearing clearance becomes larger, the grease will be easily squeezed out during operation. In this case, it is usually accompanied by abnormal noise or shaking of the rotating equipment.

2. Treatment method for oil leakage of slewing bearing

1) If the seal is aged or damaged, it is necessary to disassemble the old part and clean the sealing groove, and then insert the new seal into the sealing groove completely.

2) If the leakage of the rotary motor causes the dilution or deterioration of the lubricating oil, the rotary motor must be repaired and the grease of the entire rotary gear ring must be replaced.

3) In case of leakage caused by improper selection of grease, all the grease in the rotary gear ring should be replaced, and the same grease should also be used in the bearing cavity.

4) According to the operating conditions of the equipment, reasonably control the oil filling cycle to avoid excessive filling.

5) If the slewing bearing is damaged and cannot be repaired, it must be replaced with a new slewing bearing.

The above is the reason and treatment method of oil leakage of slewing bearing, hoping to solve your confusion. We should pay more attention to observation when running the equipment, and stop the operation in time if any abnormal situation is found, and usually pay attention to learning and summarizing some maintenance methods of the slewing bearing, which can prolong the life of the bearing and save you money. If you have any other questions or needs, please leave a message or call us!