The application status of rotary slewing bearing in the field of wind power generation

Wind power is a clean energy source that is attracting increasing attention and attention. As an important component, slewing bearings play a vital role in the safety and reliability of wind power equipment. This article will discuss the current application status of slewing bearings in the field of wind power generation.

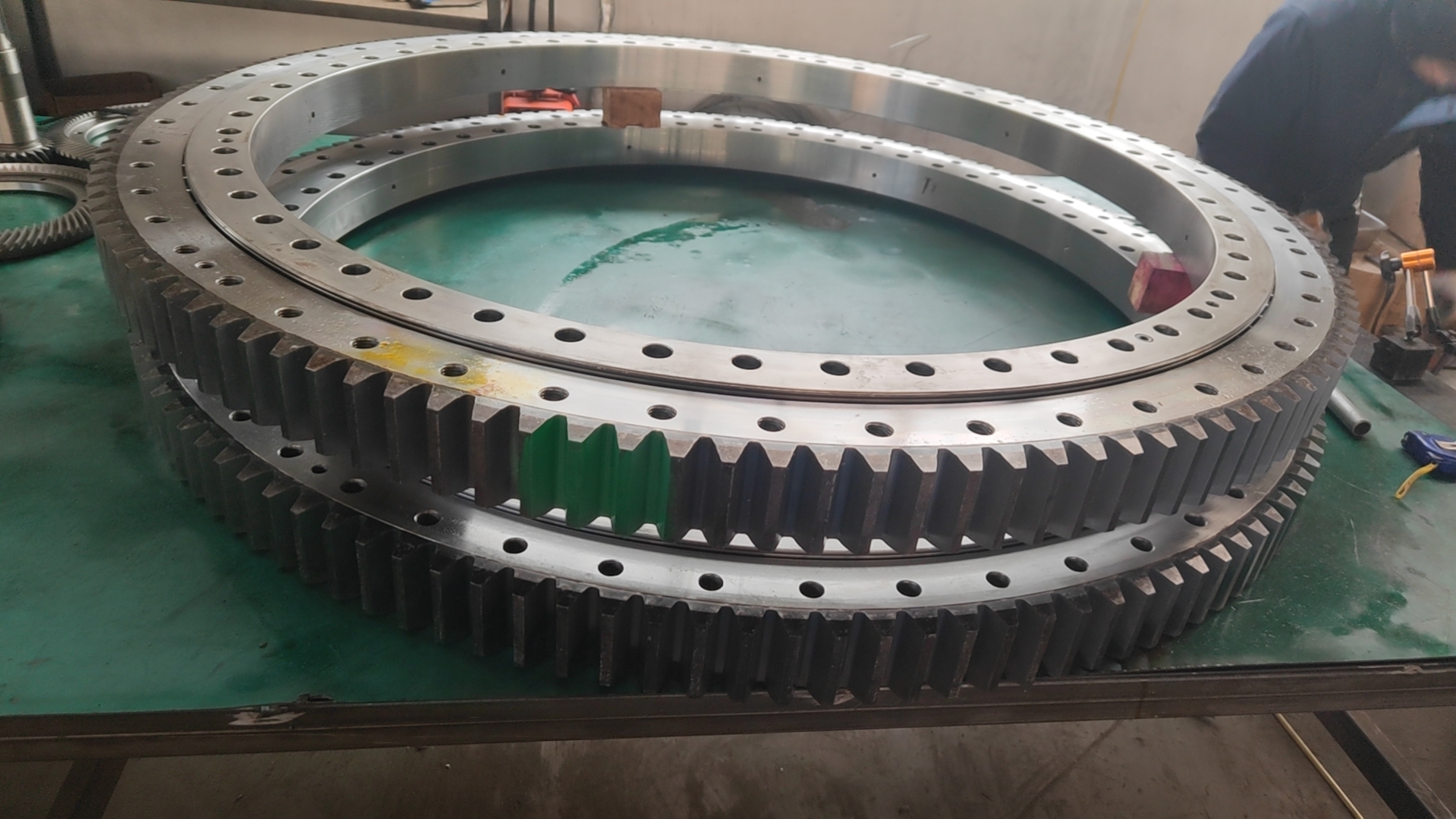

First, you need to understand the basic role of slewing bearings in wind power equipment. Xuzhou Shengjia Slewing Bearing Co., Ltd. introduced that wind power equipment usually consists of towers, rotors, shafts, blades and other parts, and slewing bearings are important components that connect the rotor and tower. It not only needs to bear the weight of the large rotor, but also needs to withstand the rotation and thrust of the rotor due to wind force. Therefore, the quality and performance of the slewing bearing are very high.

In wind power generation equipment, slewing bearings are usually divided into two types, one is a single-point contact ball slewing bearing, and the other is a roller slewing bearing. The two types of slewing bearings have their own characteristics and should be selected according to specific usage scenarios and needs.

At present, the application of slewing bearings in the field of wind power generation has been quite mature. With the continuous advancement of wind power technology, the quality and performance of slewing bearings are also constantly improving. On the one hand, the load capacity of the slewing bearing has been greatly enhanced and can withstand greater rotor weight and wind thrust; on the other hand, the service life of the slewing bearing has also been greatly improved to meet the needs of long-term operation.

The application status of slewing bearings is mainly reflected in the following aspects:

First, the load capacity of slewing bearings has been greatly improved. At present, the rotor weight of wind power generation equipment has become larger and larger, so higher requirements have been put forward for the load capacity of slewing bearings. Slewing bearings can already bear weights exceeding tens of tons, greatly improving the reliability and stability of wind power equipment.

Secondly, the service life of the slewing bearing has been significantly extended. As wind power equipment becomes larger and more efficient, the requirements for the service life of slewing bearings are also getting higher and higher. At present, slewing bearings have a service life of several decades, greatly reducing equipment maintenance and replacement costs.

In addition, the reliability and safety of slewing ring bearings have also been improved. Wind power equipment operates in a very harsh environment and needs to be able to withstand strong winds and severe weather. Slewing ring bearings have been optimized and improved in material selection, manufacturing processes and protective measures to maintain good operating conditions in harsh environments.

Generally speaking, the application status of slewing bearings in the field of wind power generation is quite mature, and the quality and performance have been greatly improved. The load capacity, service life and reliability of slewing bearings have been greatly enhanced, playing an important role in the safety and reliability of wind power equipment. With the continuous development of wind power generation technology, it is believed that slewing bearings will have broader application prospects in the future.