The reasons and Precaution for shaking problem during the slewing bearing rotating

The reasons and Precaution for shaking problem during the slewing bearing rotating

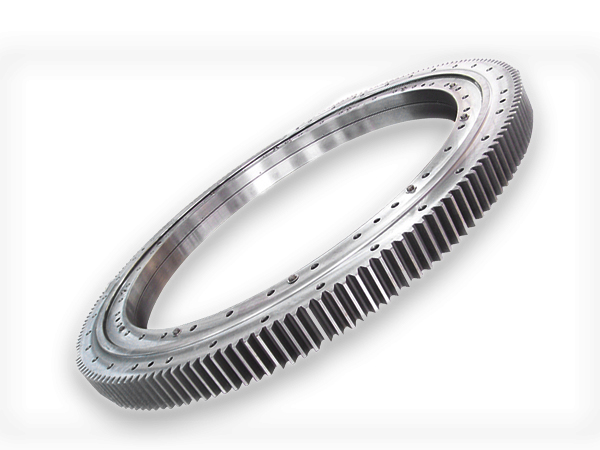

Slewing bearing is also called a slewing ring or turntable bearing. It is one of the important components in modern engineering mechanical rotation devices, such as excavators, cranes, pile drivers, flat -ground machines, road pressing machines, tunnels, excavations, tower cranes, etc. Due to the large load operation during operation, and the working environment is relatively harsh, the operation is not smooth (jitter) and issues a noise (abnormal noise) failure. So what is the reason for the shaking during the slewing bearing operation? How to prevent it? Let's follow the editor to learn about it.

1. The reasons for the shake during working

1) Internal processing accuracy

The processing accuracy of the internal steel balls inside the slewing bearing is not high and the processing accuracy of the internal raceway, or there are quality defects and lack of lubricating oil roller and block collision in the raceway, which directly affects the smoothness and noise of the slewing bearing. Therefore, when checking the slewing bearing, sometimes the frequency of failure is reduced by replacing steel balls.

2. The processing of the gear is not precise enough

The accuracy level of the slewing bearing should be between level 7 and 11, and it determines the stability of the transmission, the uniformity of the load distribution, and the accuracy of the transmission. The higher of the the gear accuracy, the more densely the exposure to the tooth surface of the tooth surface, so that the noise value is reduced and the operation stability is improved.

3. Welding defect in the upper and lower support

If the quality of the welding is unqualified, the weld defects need to be repaired and welded. During the repair of welding repair, it will not only produce a new welding stress, but also the plane degree of the machine processing and installation surface. At the same time, the current during the welding can also cause a certain amount damage for internal rolling bodies and rolling trails. In addition, in the preparation error generated in the manufacturing assembly, the pre -tightening of axis and bolts in the on -site installation will also produce abnormal noise or jitter.

4. The quality of gear and startup motor

After the gear is loaded for a long time, a small metal or strip metal iron chips will be dropped near the tooth surface line, forming an erosion or teeth. The increasing working time of the tooth surface is continuously expanded to damage the meshing tooth shape. The noise and impact during turning increased, and the metal particles that were impacted by the reciprocated and repeatedly accelerated the wear of the tooth surface to form a vicious circle. In addition, the manufacturing and assembly of the motor in the turning mechanism have their own defects to produce impact jitter. The meshing process of the drive wheel and support is unstable.

Second, prevention measures for the shaking

1. Installation and running

Installation of the rotation branch to undertake high -intensity bolts, bolts and nuts shall meet the requirements of GB3098.1 and GB3098.2 standards. Before the bolt is tightened, the large and small gear meshing (side gap) must be performed, and the slewing bearing should be met with the requirements of the small gear meshing. Tighten the installation bolts at 180 °. The installation plane must be cleaned and flat, and there must be no sundries such as wool edges, iron dumbs. Considering the impact of wind power on the slewing bearing, if the prescribed wind operation or stopping operations cannot rotate freely with the wind, this may damage the gear or rotation slewing bearing, and a safety accident will be seriously occurred. Therefore, detailed inspections should be done in installation and operation.

2. Fastening bolt

In addition to the pre -tightening force, the connection bolt of the slewing bearing and the upper and lower branches has a axial pulse load, which will cause the bolt long or the connection surface deformation, causing the bolt to loosen. The bolt connection is not reached to increase the axial gap after the requirements are not required. Therefore, it is necessary to regularly check the tightening of the slewing bearing bolt to achieve the prescribed pre-tightening force. The pre-tightening force is generally 400-500N.M.

3. slewing bearing internal lubrication

In daily use, in the instructions in a timely and on time in the instruction manual, each component should be lubricated in accordance with the lubricant, lubrication method, and lubrication cycle. Corresponding to the ball slewing bearing is generally injected every 100 hours, and the roller slewing bearing is added every 50 hours. For a special working environment with large dust, high humidity, and high temperature difference, the lubrication cycle should be shortened. Each lubrication must be filled until the lubricating oil is exuded. At the same time, you need to slowly rotate the slewing bearing to fill the grease evenly. By adding lubricating oil maintenance, the friction between the gears can be reduced, the wear speed of the gear can be reduced, and the formed oil film can also play a role in the shock absorption ring and eliminate part of the vibration energy generated during operation. In addition, the lubricant film can also lubricate and clean each friction surface to prevent rust, eliminating the effect of iron dumbs on the surface of friction. This reduces the life of running friction and noise.

The above is the analysis and explanation of the reasons and preventive measures of the slewing bearing. I hope it can help you. Luoyang Heng Guan Bearing is a comprehensive physical enterprise that integrates design, R & D, production, sales and service. It is mainly engaged in various high -precision slewing bearing, large thrust ball bearings, non -standard alien bearing and other products, and also provides customers with customized exclusive bearing products. Everyone is welcome to call for detailed consultation.