What are the characteristics of cross roller slewing bearing?

What are the characteristics of cross cylindrical roller turntable bearing?

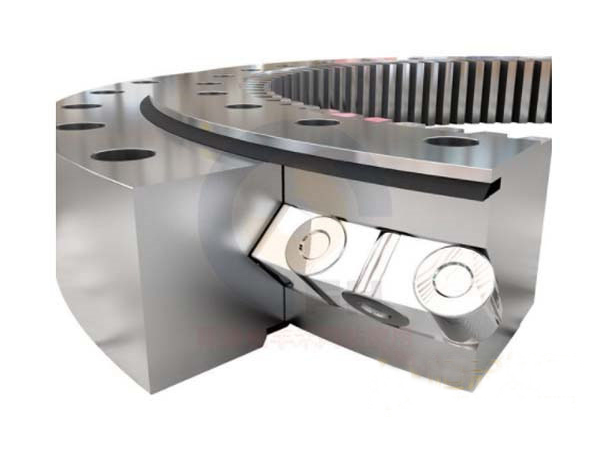

The cross cylindrical roller turntable bearing is a type of cross roller bearings. It is mainly composed of two seats and single row cross -placed cylindrical rollers, holding racks (isolation blocks), sealing device and other parts. Widely used on the waist turning of the carrier and other robots, the rotation disc, which requires good accuracy and rigidity on the automation line, the welding station turning table, the large diameter rotation plate, the tower crane with a medium -sized diameter, and the car crane. Below, follow the editor to learn about the characteristics of the cross -cylindrical roller turntable bearing.

1. It can carry the load in all directions

The cross -cylinder roller turntable bearing only has one rolling carp, but the rolling body is a short cylindrical roller. The axis of the adjacent roller is arranged at 90 °. Axial force, half of the upward axial force, this bearing can withstand radius, axial force, and overturning torque. The length of the cylindrical roller should be 0.5 ~ 1mm than its diameter. The overall structure is simple and rigid.

2. Isolation block

Cross -cylindrical roller turntable bearings can bring isolation blocks or without isolation blocks. Most of the foreign use in construction machinery does not have isolation blocks.

3. Adjust the gap

Most of the cross -cylindrical roller bearings are made of components to facilitate the installation of rolling bodies and adjusting the gap. However, there are also overall. Like four -point contact ball, use the filling hole to fill the roller, and use the option to adjust the axial gap. After the roller is full, there are also some gaps. The total gap between the roller is usually about 0.5D in the direction of the circular.

4. Effectively prevent the increase in rotating torque

The internal structure of the cross -cylindrical roller turntable bearing is arranged vertically with a 90 ° roller, and the interval holder or isolation block is equipped between the roller. Increase the torque. In addition, the phenomenon of contact or locking the roller party will not occur.

5. High -precision rotation

Non -standard cross -rolling bearing. At the same time, because the inner and outer ring is a divided structure, the gap can be adjusted. Even if the pre -pressure is applied, a high -precision rotation movement can be obtained.

6. Easy operation

The segmented inner ring or outer ring is fixed with the cross -roller shaft ring after loading the roller and the interval holder to prevent each other from being separated.

7. Prevent roller side inversion

By the interval holder, the mutual friction between the roller disappears, and also prevents the side inversion of the roller, so as to obtain a stable rotating torque.

8. Greatly improved rigidity

Unlike the use of dual -column -thin angle contact ball bearings, because the roller is arranged vertically, it can withstand the load in all directions with only one cross -rolling shaft ring, and the rigidity increases by more than 3 to 4 times.

The above is the characteristics of the characteristics of cross -cylindrical roller turntable bearing. In fact, the structure and application of the cross -cylindrical roller turntable bearing is basically the same as the four -point contact ball -turntable bearings, but the rolling body changes from steel balls to roller, rolling body and The contact of the inner and outer circle changes from point contact to line contact.