bearing slewing

-

Gold medal merchants manufacture turntable bearings

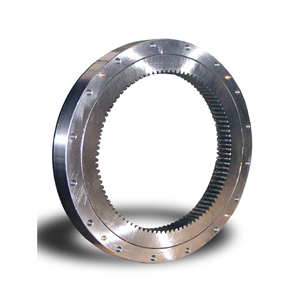

Slewing bearing is an important "joint" of the crane. Various loads and moments on the working device need to be transmitted to the chassis through the slewing bearing. Because the slewing bearing is overloaded, it is also the part where the crane is prone to failure, so it is necessary to install a new slewing bearing after long-term use. Truck cranes, crawler cranes and other heavy construction cranes are usually using large single row four-point contact ball slewing ring bearing. This type of slewing bearing can bear larger axial load, radial load and tilting moment, enabling crane to lift heavy loads stably and reliably.

Email Details -

Carrying large customizable heavy duty machinery slewing bearings

The single-row crossed roller slewing bearing is composed of two seat rings. It has a compact structure, light weight, high manufacturing precision, small assembly clearance, and high requirements for installation accuracy. The rollers are arranged in a 1:1 cross and can bear the bearings at the same time. It has axial force, overturning moment and large radial force, and is widely used in lifting, transportation and engineering machinery products.

Email Details -

Trailers KLK turntable ball bearing

1. light weight 2. Can transmit both axial forces and the thrust and pull forces generated during drive. 3. Flexible rotation 4. Can be matched with transmission gears, applied to industrial machines

ball bearing turntables turntable ball bearing ball bearing turntable rings turntable ball bearing slewingEmail Details -

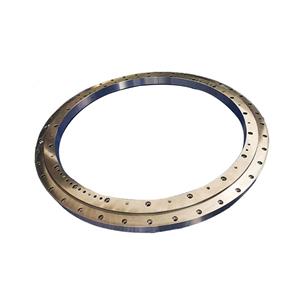

Thin Type slewing ball bearing with Flange Slewing Ring 23041101

1. With good moment, thrust and radial loading capacity. 2. Suitable for light to medium duty. 3. Easy installation 4. light weight and thin section 5. Flexible rotation

Email Details -

High Precision Low Noise Slew Bearing For CT Scanner Machine

Slew Bearing For CT Scanner Machine is featured with high precision, high speed and low noise. Firstly, the 42CrMo quenched and tempered material is used to make the material performance better and more stable, which guarantees the product quality from the source; Secondly, the product raceway and appearance are comprehensively polished to ensure high product precision; Thirdly, for the product's silent requirements, a special segmented nylon cage device is used to lock the ball in the cage pocket while ensuring that the steel ball can rotate freely, thereby reducing the noise impact caused by the free movement of the cage in the raceway. Reduce rotating noise. Through the above efforts, we ensure that the finished products of the slewing ring meet various technical requirements.

Email Details -

Yaw Bearing For Wind Turbine Generator

The wind turbine yaw bearing is installed at the connection between the tower and the cockpit, and the pitch bearing is installed at the connection between the root of each blade and the hub. Each wind turbine uses one set of yaw bearing and three sets of pitch bearing. The material of the yaw and pitch bearing rings is 42CrMo, the heat treatment adopts the overall quenching and tempering treatment, and the surface of the raceway is quenched. The force of yaw and pitch bearings is complex, and the impact and vibration are relatively large. Therefore, the bearing is required to withstand both impact and large load. The life of the wind turbine main engine requires 20 years, and the cost of bearing installation is relatively large, so the life of the yaw and pitch bearings is required to reach 20 years. The hardness of the bearing ring base is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface quenching hardness of the raceway reaches 55-62HRC, which can increase the contact fatigue life and ensure the service life of the bearing.

yaw bearing wind turbine slewing bearing Main shaft bearing for wind turbine ball bearing slewing ringEmail Details