turntable bearing

-

High technology and high precision rotary bearings Experienced manufacturer

Crossed roller slewing bearing products have remarkable features. 1. It shows high bearing capacity and can withstand large loads. 2. The product has high rotation accuracy to ensure smooth and error-free operation. Its structure is compact and reliable, which improves its service life. 3. This product has small friction loss, can reduce energy consumption and improve economic benefits. 4. It saves installation space, has strong adaptability and is easy to deploy. The high rotation speed capability can meet the efficient operation needs of various types of equipment. It has strong impact resistance and can operate stably even in harsh working environments. 5. Adequate lubrication, effectively reducing wear and extending service life

Email Details -

Customizable Flange plate+Slewing bearing

In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings.

Flange plate and Slewing bearing slewing bearing manufacturer crane slewing bearing custom slewing bearingEmail Details -

Customizable crane slewing bearings

The slewing bearing of the crane is a large bearing that can withstand comprehensive loads and can withstand large axial, radial loads and overturning moments at the same time. This product supports customization, and various slewing bearings with special structures can be designed, developed and produced according to user needs.

Professional slewing bearing manufacturer excavator swing bearing slewing ring Large bearing capacity slewing bearingEmail Details -

Large diameter Crane slewing bearing

The three-row roller large slewing bearing is a high-performance bearing product designed to withstand large oil loads, overturning moments and radial loads. Its processing technology is complex but sophisticated, usually including material selection, forging, heat treatment, finishing and surface mounting.

Email Details -

Customizable large slewing bearings

Turntable bearings, also called slewing bearings, are key components in mechanical equipment. Its features include strong load-bearing capacity, smooth operation and high precision. It mainly consists of an inner ring, an outer ring, rolling elements and a cage. The inner ring and outer ring transmit torque and bear load through rolling elements to realize the rotary motion of the equipment. It is widely used in heavy machinery, wind power, port equipment and other fields. Its excellent performance ensures the efficient and stable operation of the equipment and provides strong support for the development of modern industry. HGB Company manufactures standard and custom slewing bearings in various designs with outer diameters from 200mm-10000mm to meet the requirements of specific applications.

Email Details -

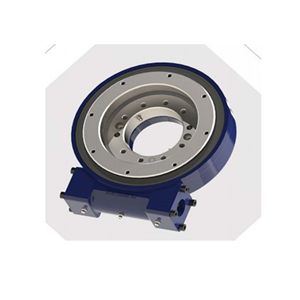

FWA series slewing drive

FWA series reducer adopts closed housing and skeleton oil seal ring, which can effectively prevent dust and water from entering the reducer, requiring less maintenance.

Email Details -

FWE series slewing drive

Applications of FWE series slewing drive:Applications such as truck cranes, aerial work platforms, drilling rigs, rotary platforms, etc.

Email Details -

WEA series slewing drive

Slewing drives can be widely used in engineering machinery and new energy fields such as heavy-duty flatbed transporters, container cranes, truck cranes, aerial work vehicles, solar power generation systems, etc. (WEA series is a heavy-duty slewing drive with large torque and self-locking function)

Email Details -

SE series slewing drive

The slewing drive device is a new type of slewing product, usually also called a slewing bearing, which is usually composed of worm, slewing bearing, housing, motor and other components. Since the core component adopts a slewing bearing, it can withstand axial force, radial force and overturning moment at the same time. (The SE series is a fence-type slewing drive, and the worm gear transmission can achieve reverse self-locking

Email Details