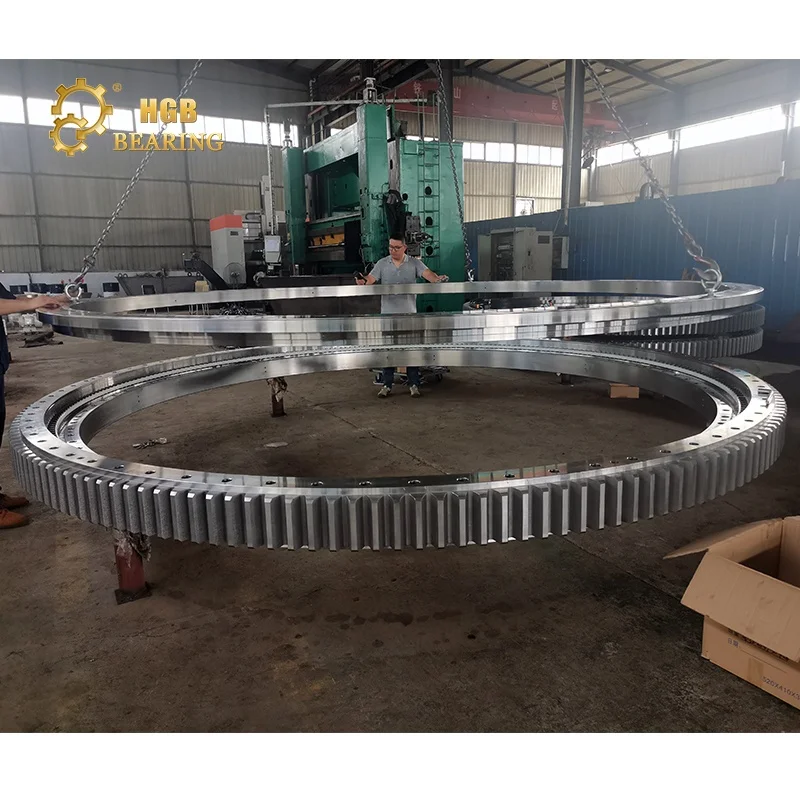

High-quality services for heavy machinery can be customized for slewing bearings

- LYHGB

- Luoyang

- 45 days

- 4000 sets/ month

The three-row roller slewing bearing consists of three races, with upper and lower and radial raceways separated, so that the load of each row of rollers can be accurately determined. It can withstand various loads at the same time and has the largest carrying capacity among the four structural products. It has relatively large shaft and radial dimensions and a solid structure. It is especially suitable for heavy machinery requiring larger diameters, such as bucket wheel reclaimers, Wheeled cranes, port cranes, ladle rotary tables and large-tonnage truck cranes and other machinery.

Product Introduction

As a key structural component of many types of mechanical vehicles, the slewing bearing is closely related to the operating efficiency of the machinery and is inextricably linked to the economic benefits of the user. In order to meet the performance characteristics of different types of mechanical vehicles, there are also certain structural differences in the bearings. The structural advantages of the three-row roller slewing bearing are introduced below:

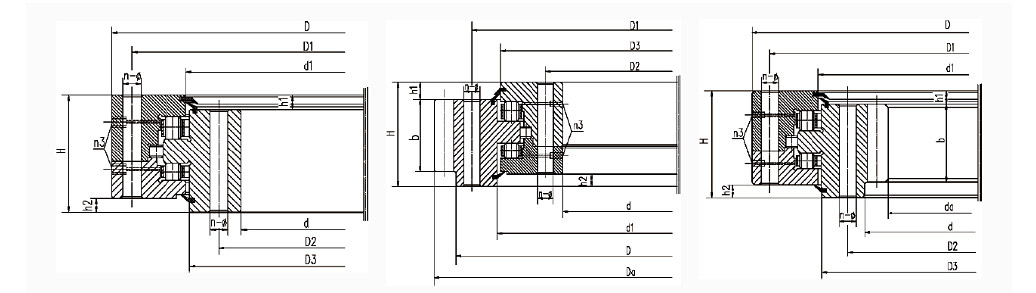

The three-row roller slewing bearing includes an upper ring and a lower ring. The upper ring is connected to the lower ring through bolts to form an outer ring structure. The gear ring is located in the outer ring structure. There is a boss on the side of the gear ring. The top of the boss is connected to the upper ring. There is an upper raceway between them. There is an upper row of rollers in the middle of the upper raceway. There is a lower raceway between the bottom of the boss and the lower ring. There is a lower row of rollers in the lower raceway. The sides of the boss and the outer ring There is a radial raceway between the structures, a radial roller is placed in the middle of the radial raceway, a double sealing ring is connected to the inner edge of the upper ring and the upper end of the gear ring, and a lower sealing belt is connected to the lower end of the gear ring.

The three-row roller slewing bearing has a clear division of load-bearing capacity of each rolling element. The upper and lower rows of rollers carry a load of 90°, giving full play to the load-bearing efficiency of each load-bearing roller. Therefore, it has a large load-bearing capacity of axial force, radial force and overturning moment. capabilities, meeting the 360° requirements for slewing bearings of engineering machinery, especially cranes, stackers, ladle slewing tables, etc.

Application

It is especially suitable for heavy machinery requiring larger diameter, such as

bucket wheel stacker and declaimer,

wheel crane,

marine crane,

port crane,

ladle turret,

large tonnage truck crane,

heavy machinery and so on

Features

1. Compared with the cross-roller bearing, under the same bearing diameter, the number of rolling elements (contact points) is increased, thereby reducing the load on each rolling element; After the contact is changed to line contact, the contact stress can be reduced and the bearing capacity can be improved.

2. Since the radial force and the axial force are borne by the two rows of rollers respectively, the direction of the reaction force is consistent with the main direction of the load on the bearing, so the contact load between the rollers and the raceway can be reduced.

3. Under the same load, it has smaller dimensions, smaller section and lighter weight than other types of supports, which can save materials and reduce material costs.

4. The raceway of the rolling ring is a plane and a cylindrical surface, which is more convenient to process.

5. In addition to bearing radial force, the vertical roller also has the guiding function of bearing the tilting moment.

Technical Parameters

why choose us

1. Quality Assurance

High grade raw material selection and strict material inspection.

The equipment can meet all the processing procedures and fully achieve production according to the drawings.

2. Reasonable Price

The price is the most favorable under the same quality.

The quality is the best under the same price.

3. Delivery Time Guarantee

Efficient production arrangement and inspection to guarantee the timely shippment