What is a slewing bearing? (All the knowledge you need about slewing bearings)

1. Structure of slewing bearings

Slewing bearings are also called turntable bearings and turntables. The English name is slewing bearing/slewing ring. It is a large bearing that can withstand comprehensive loads. Its diameter is usually 0.4m~10m, and it can withstand large axial, radial loads and overturning moments at the same time.

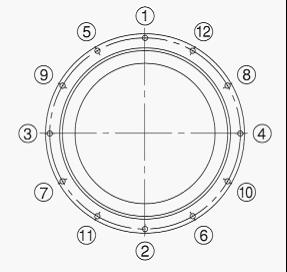

2. Names and positions of various components of slewing bearings

According to the external structure, there are three types of turntable bearings: toothless, externally toothed, and internally toothed. According to the internal structure, it can be divided into four series with the following features:

(1) Four-point contact ball bearing: has a high static load capacity and provides smooth rotation.

(2) Double-row angular contact ball bearing: easy to assemble, can withstand large axial force and overturning moment, suitable for medium and above loading and unloading machinery, such as tower cranes, truck cranes, etc.

(3) Cross cylindrical (tapered) roller slewing bearing: has a high dynamic load capacity and can obtain greater support rigidity and rotation accuracy through preload.

(4) Three-row cylindrical roller combination bearing: has extremely high load capacity, the bearing diameter can be greatly reduced under the same force, making the main machine structure more compact.

3. How to choose the type of slewing bearing?

Both are rolling bearings, what is the difference between turntable bearings and ordinary rolling bearings?

(1) A set of slewing bearings can withstand combined loads in multiple directions

(2) The operating speed of the bearings is generally not high

(3) Generally, continuous rotation is not performed, and only back and forth rotation is performed within a certain angle

(4) The installation is fastened to the upper and lower supports by screws or bolts

(5) The structure is compact and the height is small

(6) There is no central pivot, and the middle space can be used to install other components.

(7) Easy installation and maintenance, long service life

4. Material of slewing bearing

The nature and quality of the raw materials have a great influence on the performance and service life of the slewing bearing. BRS only uses materials from qualified suppliers, and we will conduct strict inspections on forgings, including ultrasonic inspection, hardness inspection and metallographic inspection.

For precision slewing bearing materials, such as cross roller bearings and harmonic reducer bearings, BRS uses GCr15 bearing steel as raw material. As a representative steel of high carbon chromium bearing steel, GCr15 has a low alloy content and good comprehensive performance. After quenching and low temperature tempering, GCr15 bearing steel has high hardness, uniform structure, good wear resistance and high contact fatigue performance. It is usually used to manufacture precision bearing rings and rolling elements. GCr15 has high requirements for smelting quality, and the content and distribution of sulfur, phosphorus and non-metallic inclusions must be strictly controlled, which will have a significant impact on the service life of bearing steel.

5. For slewing bearing materials, BRS usually uses 50Mn or 42CrMo as raw materials.

50Mn is a high-quality carbon structural steel. It has high strength, elasticity and hardness, and is often used after quenching and tempering. 50Mn has poor welding performance and has a tendency to overheat sensitivity and temper brittleness. 50Mn is often used to manufacture components with high requirements for wear resistance and load capacity, such as gears and gear shafts.

42CrMo material is an alloy steel that is very suitable for forging processing. It has high strength, high hardenability and good toughness. 42CrMo has little deformation during quenching and has high creep strength and lasting strength at high temperatures. Compared with 50Mn, 42CrMo has better fatigue strength, but the cost is higher.

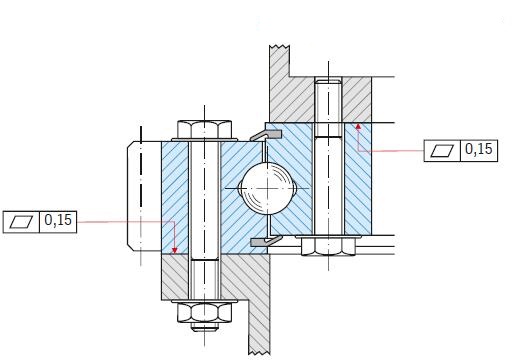

6. Installation of slewing bearing

Before installing the slewing bearing, the mating surface should be checked. The components supporting the turntable bearing should have sufficient rigidity, and the mating surface should be machined to achieve the flatness and inclination required by the relevant standards. Each set of turntable bearings will be marked with the quenching soft band "S". When installing, the soft band should be placed in the non-load area. When installing, the bearing should be radially positioned first, then the mounting bolts should be tightened crosswise, and the rotation of the turntable bearing should be checked. To ensure that the turntable bearing rotates smoothly, the gear meshing should be checked before the mounting bolts are fully tightened. The prestress of the tightening bolts should be 70% of the yield limit of the bolt material. BRS's slewing bearing has been greased before leaving the factory. Under normal circumstances, the bearing should be checked and greased once after being installed and put into operation for 100 hours (how to add grease), and then repeated every 500 hours of continuous operation. For turntable bearings in high temperature environments, the grease replenishing cycle should be appropriately shortened when working. Grease should also be replenished when the bearings are stored for a long time or the machine is stopped for a long time.

7. Application of slewing bearing

Slewing bearings are widely used in large slewing devices of equipment such as lifting machinery, mining machinery, construction machinery, port machinery, ship machinery, high-precision radar antenna bases, missile launchers and wind turbines. At the same time, we can also design, develop and produce slewing bearings of various special structures according to the specific requirements of users.