spur gear

-

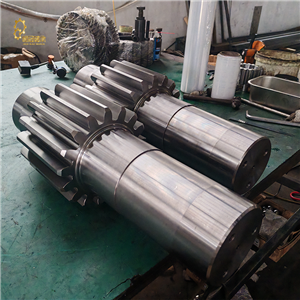

High precision gear shaft China source factory can be customized to process a variety of models

1.The gear shaft is an important component in mechanical transmission. It transmits power and energy through the meshing of gears. torque. The gear shaft is the shaft on which the gear is installed. Its main function is to support the gear and connect the gear to the The rotational force is transmitted. The gear shaft is usually made of a long strip of metal material. Has certain strength and stiffness. The end of the gear shaft is connected to the driving device (such as a motor), The other end is connected to the driven device (such as mechanical equipment). When the drive unit rotates, by Due to the meshing effect of the gears, the rotational force of the driving wheel and the driven wheel will be transmitted along the gear shaft. 2.1.Our company has many years of manufacturing and production experience, complete equipment, and a professional technical team. We have cooperated with many new and old customers at home and abroad for many times. We can design and produce according to the required drawings provided by customers to meet customer needs. We also have one-to-one service, please believe us. If you have needs, you can find out first. Customers are welcome to consult.

Email Details -

Customizable gear shaft

Customizable gear shafts are highly flexible: size, material and performance can be precisely customized according to customer needs to meet diverse transmission needs; advanced technology is used to ensure high precision and long life; compact structure and high transmission efficiency make it an ideal choice for improving mechanical performance and reducing maintenance costs.

Email Details -

Customizable forged steel gears

Customizable forged steel gear is a high-performance product designed to meet various industrial needs. Made of high-quality forged steel material and finely processed, it has excellent load-bearing capacity and durability.

Email Details -

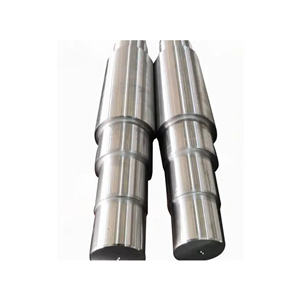

Factory can customize high quality roller shaft

Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries.

Email Details -

Professional manufacturers can customize gears wheel

Our company has professional technical personnel, complete equipment, and many years of production experience. We have cooperated with many customers both domestically and internationally, and have high quality assurance. Gears can be produced according to the drawings provided by customers, including spur gears, helical gears, herringbone gears, etc. We welcome inquiries.

Email Details -

High quality customizable helical gears or spur gear

1.Gears are mechanical components with teeth on the rim that can continuously mesh to transmit motion and power. The application of gears in transmission appeared very early. 2.According to specifications or sizes, gear models are divided into standard and non-standard;According to different measurement units at home and abroad, gear models are divided into two types: metric and imperial.

Email Details -

Customizable large spur gears high quality ring gear and pinion gear wheel supplier

1.A spur gear is a simple gear with parallel teeth and a gear axis. It is used to transmit power between parallel shafts. Spur gears are primarily used to reduce speed and increase torque. Spur gears have the advantages of simple design, easy manufacturing, low cost, high efficiency, and can achieve various transmission ratios, but the disadvantage is that they are noisy. Helical gears have teeth that are inclined to the axis of the gear. For the same tooth width, helical gears have longer teeth than spur gears. Therefore, more power can be transferred between parallel shafts than with spur gears. The advantages of helical gears are higher load carrying capacity and contact ratio compared to spur gears. Smoother and quieter than spur gears. and have good accuracy levels. The disadvantage of helical gears is that they are less efficient compared to spur gears. The helix angle also increases the axial thrust on the shaft. 2.Our company can produce different type pinion gears such as spur gear, helical gear, worm gear according to the customer's drawing and requirements. Our product is highly appreciated amongst customers for its dimensional accuracy, excellent strength and high performance. Teeth quenching, teeth grinding and surface treatment like oxide, nitriding, sandblasting are also available.

Email Details -

Factory customizable long life high quality gear shaft

Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries.

Email Details -

Factory can customize spur or helical or herringbone gears according to customer needs

1.Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear and shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries. 2.A spur gear is a simple gear with parallel teeth and a gear axis. It is used to transmit power between parallel shafts. Spur gears are primarily used to reduce speed and increase torque. They are also used at high speeds in some consumer products. The following are the applications of spur gears in several products: mixers, washing machines, automobiles, bicycles, mechanical clocks, etc. Helical gears have teeth that are inclined to the axis of the gear. For the same tooth width, helical gears have longer teeth than spur gears. Therefore, they can transmit more power between parallel shafts than spur gears. Helical gears are used to transmit heavy loads between parallel shafts at very high rotational speeds. The following are the applications of helical gears in various products. Automotive gearboxes, printing and other machinery, conveyors and elevators, factory automation, etc. Double helical gears have opposing helical teeth with grooves between them. Herringbone gears, on the other hand, have no grooves. Both gear types are used to transmit power between parallel shafts. Compared with helical gears, herringbone gears and double helical gears have the advantage of balancing bidirectional axial thrust. Therefore, they are used in applications with high load-carrying capacity requirements, such as differentials and heavy machinery.

Email Details