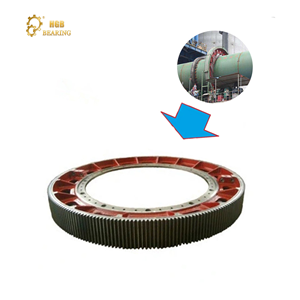

large gear ring

-

Segmented large gear rings

Segmented large gear rings are important components in industrial reducers, mainly used to drive large rotating systems such as dryers, rotary kilns, horizontal mills, etc.

Email Details -

Casting or forging customizable large gear rings

Forged or cast customizable large gear rings are important products in the field of mechanical manufacturing, with a wide range of applications and unique advantages.

Email Details -

High quality customizable helical gears or spur gear

1.Gears are mechanical components with teeth on the rim that can continuously mesh to transmit motion and power. The application of gears in transmission appeared very early. 2.According to specifications or sizes, gear models are divided into standard and non-standard;According to different measurement units at home and abroad, gear models are divided into two types: metric and imperial.

Email Details -

Factory customizable large gear wheel big ring gear Making replacement repairs

1.Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries. 2.Gears are widely used in various mechanical transmission systems, including automobiles, aviation, rail transit, engineering machinery, ships, wind power, robots and other fields. As an indispensable component in the mechanical transmission system, gears have always been one of the core technologies in the field of mechanical manufacturing.

Email Details -

Drying machine large gear ring

In dryers and dryers, the role of the large gear ring is crucial, usually used to transmit power and support rotating components. Through reasonable material selection, design, and maintenance, the stable and reliable performance of the large gear ring can be ensured, providing strong support for the long-term operation of the equipment. The large gear ring transmits the power of the motor to the rotating parts of the equipment through meshing with the small gear, thereby driving the operation of the equipment. The large gear ring is generally made of high-strength materials, such as cast steel or alloy steel, to ensure that it can withstand the strong forces and high temperatures generated during equipment operation. The accuracy and wear resistance of the large gear ring directly affect the service life and efficiency of the equipment.

customized large gear ring girth gear Non standard customized product solution provider high quality gear ringEmail Details -

Customizable segmented large gear ring ball mill manufacturer

1.Segmented large ring gears are used to drive large rotating systems, such as dryers, rotary kilns, and horizontal mills 2.Advantages (1) Minimum vibration: The segmented large ring gear has high-precision pitch. (2)Easy to replace because the large ring gear is divided into multiple segments without having to disassemble the entire ring gear. (3)The longer service life is due to the use of appropriate size and reasonable lubrication, so that the large ring gear made of material has no wear in actual use.

Email Details -

Customizable factory production and sales of ball mill large gear rings

1.The large ring gear is one of the important components of rotary kiln, ball mill, dryer and other machinery, so the quality of the ring gear is related to the stability and service life of the ball mill and rotary kiln. 2.The large ring gear is a very critical component in the transmission device of ball mills and rotary kilns. It drives the entire cylinder to rotate at low speed for a long time. Its quality directly affects the smoothness of the transmission system of ball mills and rotary kilns, the stability of operation, and the quality of the lining. The service life and the operation rate of the kiln and the grinding mill, so the quality requirements of the large ring gear in actual production are very high.

Email Details