Casting or forging customizable large gear rings

- LYHGB

- LUOYANG,CHINA

- 45 DAYS

- 4000 SETS/ MONTH

Forged or cast customizable large gear rings are important products in the field of mechanical manufacturing, with a wide range of applications and unique advantages.

Product detial

1. Large gear rings are key components of heavy machinery and equipment such as rotary kilns and ball mills, and require long-term stable operation. Therefore, these large gear rings are usually made of high-strength and high-toughness alloy steel materials, such as

ZG45, ZG42CrM0, etc., to ensure their wear resistance and impact resistance. Through precise casting or forging processes, large gear rings can be customized according to customer drawings and dimensions to meet the needs of different

equipment.

2. Processing technology: Casting large gear rings usually adopt sand mold casting technology, pouring molten metal into the mold by gravity casting, and forming a gear ring after cooling. The forged large gear ring goes through two stages of rough forging and fine forging. The metal billet is molded into the shape of the gear ring by the pressure of the forging machine, and then goes through heat treatment, turning, grinding and other process steps to ensure the accuracy and surface quality of the gear ring.

3. Advantages and characteristics

(1) High strength and wear resistance: Using high-strength alloy steel materials, through the optimization of casting or forging process, the large gear ring has excellent wear resistance and impact resistance.

(2) Strong customization: It can be customized according to the specific needs of customers to meet the requirements of different equipment and application scenarios.

(3) Stable process: The casting and forging processes are mature and stable, which can ensure the quality and performance of the large gear ring.

Product display

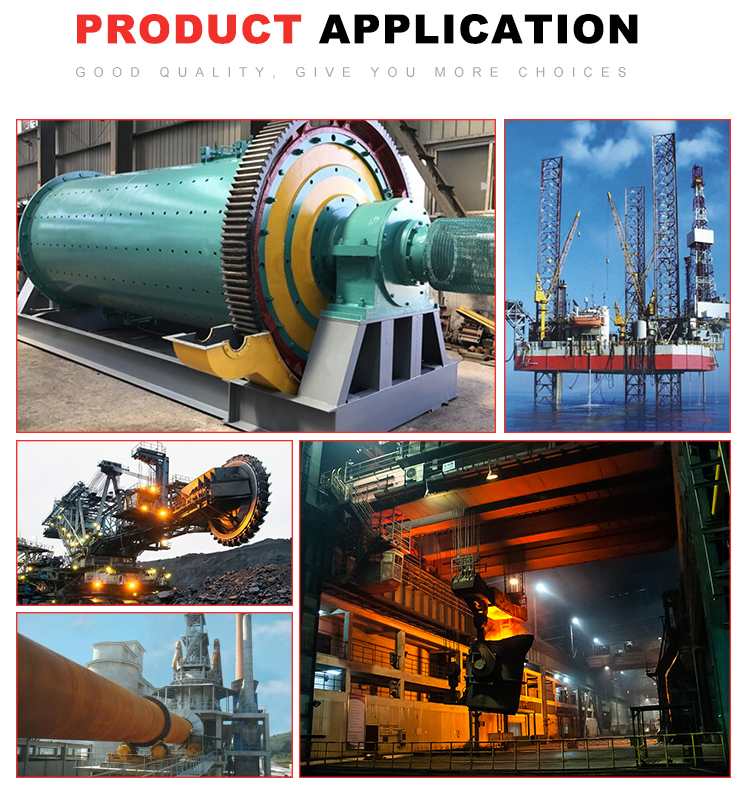

Application

The large gear ring is widely used in cement, building materials, metallurgy, petrochemical, mining machinery and other fields. It is an important accessory for heavy machinery and equipment in these industries. For example, in the cement industry, the large gear ring is the main component of the rotary kiln and ball mill, which plays a key role in ensuring the normal operation of the equipment and improving production efficiency. In addition, the large gear ring is also widely used in automobile manufacturing, shipbuilding and other fields, and is an important part of the transmission system.