Customizable forging or casting of large gears

- LYHGB

- LUOYANG,CHINA

- 45 DAYS

- 4000 SETS/ MONTH

Customizable large gears are highly personalized transmission components that can be precisely designed according to the specific needs of customers. Products include a variety of material options (such as high-strength alloy steel, high-quality carbon steel) to ensure resistance to corrosion and fatigue.

Product detial

Products include a variety of material options (such as high-strength Taijin steel, high-quality carbon steel) to ensure corrosion resistance and fatigue resistance. Large gears are processed by simple precision CNC equipment, such as hobbing machines, gear grinding machines, etc., to ensure that the tooth shape accuracy, pitch accuracy and surface roughness meet the design requirements and improve transmission efficiency and stability.

1. Processing technology

The processing technology of large gears covers multiple stages, including blank heat treatment, rough machining, finishing and finishing after heat treatment. Advanced processing technologies such as CNC hobbing, gear shaving and honing are used to ensure the accuracy and surface quality of gears. The forging process uses high temperature and high pressure to forge the metal billet to improve the density and strength of the material. The casting process uses mold pressing, heating and sintering to manufacture large gears with complex shapes.

2. Advantages and characteristics of forging or casting

Forged gears have the advantages of high strength and high toughness, which are suitable for occasions with high loads and impacts, while cast large gears can manufacture complex shapes and structures, with relatively low costs, suitable for large-scale production. Both of them can improve the transmission efficiency and reliability of gears through optimized design.

Product display

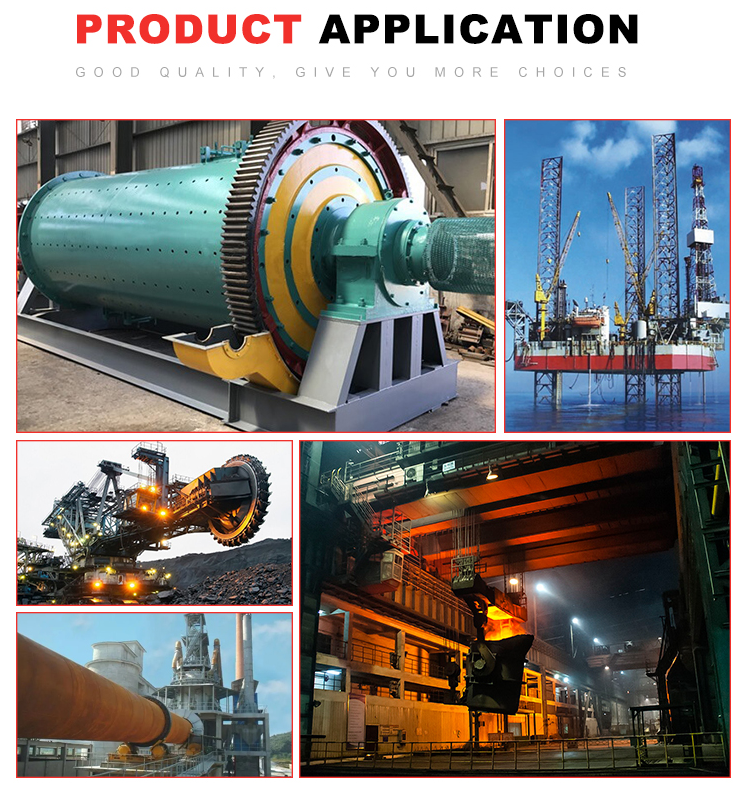

Application

Customizable large gears are widely used in mining machinery, metallurgical equipment, wind power generation, petrochemical and other fields. In mining machinery, large gears are used to drive heavy equipment such as crushers and ball mills; in wind power generation, they are used for key components such as speed increase boxes of wind turbines to ensure stable and efficient energy conversion. In addition. Large halogen wheels are also widely used in machine tools, textile machinery and printing equipment and other industries, providing strong support for the stable operation of various mechanical equipment.