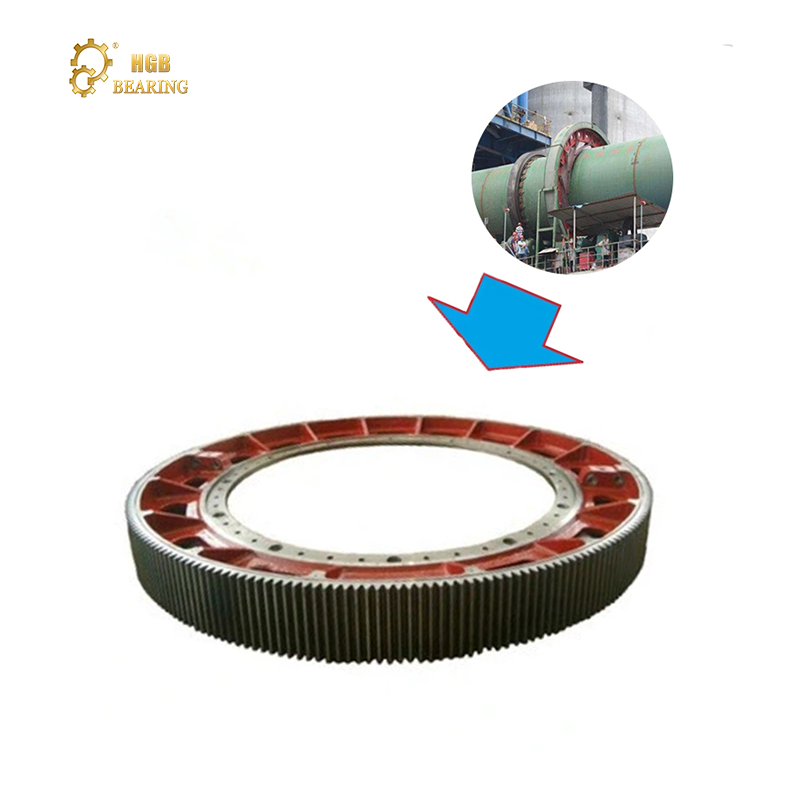

Drying machine large gear ring

- LYHGB

- LUOYANG,CHINA

- 45 DAYS

- 4000 SETS/ MONTH

In dryers and dryers, the role of the large gear ring is crucial, usually used to transmit power and support rotating components. Through reasonable material selection, design, and maintenance, the stable and reliable performance of the large gear ring can be ensured, providing strong support for the long-term operation of the equipment.

The large gear ring transmits the power of the motor to the rotating parts of the equipment through meshing with the small gear, thereby driving the operation of the equipment. The large gear ring is generally made of high-strength materials, such as cast steel or alloy steel, to ensure that it can withstand the strong forces and high temperatures generated during equipment operation. The accuracy and wear resistance of the large gear ring directly affect the service life and efficiency of the equipment.

Product detial

The large gear ring is a key component in mechanical transmission, widely used in rotary equipment such as dryers, dryers, and rotary kilns. It is made of high-strength alloy steel and has undergone carburization or hardening treatment on the surface. Ensure high load-bearing capacity and durability. The large gear ring matches with the small gear to transmit power and drive equipment rotation. Its excellent transmission stability, low impact, low vibration, and low noise characteristics make it particularly suitable for high-speed and heavy-duty machinery. In the manufacturing process, we use precision design and high-quality raw materials, with high gear smoothness. After layer by layer inspection and strict testing, we ensure product quality. The stable and reliable performance of the large gear ring provides strong support for the long-term operation of the equipment. In order to maintain the good operating condition of the large gear ring, regular maintenance and upkeep are required. This includes checking the wear of the ring gear, adding and replacing lubricating oil, and cleaning the surface of the ring gear. In addition, it is necessary to pay attention to the operating environment and usage of the equipment, avoid overload and long-term continuous operation, in order to reduce the wear and damage of the gear ring.

Product features

Application

The application fields of large gear rings are very extensive, mainly used in the following industries:

1. Construction engineering: In construction engineering, the large toothed garden is commonly used in concrete mixers, cranes, and other construction machinery to transmit power and ensure the normal operation of equipment.

2. Energy industry: Large gear rings are widely used in power generation equipment, including wind turbines, hydroelectric generators, and thermal power generators. In these devices, the large gear ring is used to convert rotational motion into electrical energy.

3. Transportation industry: Large gear rings are also used in transportation fields such as automobiles, trains, and ships. In these vehicles, large gear rings are used to transmit engine power to the wheels or propellers, enabling the movement of vehicles or ships.

4. Chemical and rotary kiln industries: The large gear ring is one of the main components of rotary kilns and ball mills, and its quality directly affects the stability and service life of the equipment.

Post maintenance of the large gear ring

1. Post maintenance

To ensure the performance and lifespan of the large gear ring, post maintenance is crucial. Regularly check the wear of the gear ring and replace severely worn components in a timely manner. Keep the gear ring clean and avoid the accumulation of impurities and dust. In addition, regularly apply lubricating oil to reduce friction and wear, ensuring smooth operation of the ring gear.

2. Precautions

When performing maintenance on the large gear ring, it is essential to pay attention to safety. Avoid maintenance operations during equipment operation to prevent accidents. Meanwhile, choose high-quality lubricants and accessories to ensure effective maintenance. Follow the manufacturer's maintenance recommendations and do not disassemble or modify the ring gear without authorization. To ensure its normal operation and safety.