Bearing cage

- LYHGB

- LUOYANG,CHINA

- 10 DAYS

- 4000 SETS/ MONTH

The bearing cage is an important component of the bearing, used to fix and guide the movement of rolling elements (such as balls or rollers). When selecting a bearing cage, it is necessary to comprehensively consider factors such as specific application scenarios, bearing types, operating temperature, loads and economy to ensure the normal operation and service life of the bearing.

Product detial

1. Bearing plastic cages are made of engineering plastic materials, such as nylon, PEEK, etc., with a variety of specifications and models, suitable for different types of bearings. Flexible design, can be directly injection molded complex structures, convenient for bearing optimization design.

Advantages and characteristics:

(1) Light weight: Plastic cages are lighter than metal cages, which helps to improve the flexibility and energy saving effect of bearings.

(2) Low noise: The friction coefficient between plastic and rolling elements is small, and the noise is low during operation, which is the first choice for silent bearings.

(3) Wear resistance: Plastic cages have good wear resistance and can extend the service life of bearings.

(4) Self-lubrication: Some plastic cages can store lubricating oil, achieve self-lubrication, and simplify the lubrication system of the host.

(5) Easy assembly and disassembly: The plastic cage has good elasticity and is easy to assemble and disassemble, which improves the convenience of bearing maintenance.

(6) Acid and alkali corrosion resistance: Engineering plastics have better acid and alkali corrosion resistance than metals and are suitable for use in harsh environments such as chemical machinery.

(7) Good economic efficiency: Plastic cages have low production costs and significant economic benefits.

2. Copper cages: Made of brass material, they have high tensile strength and mechanical strength, which is comparable to steel plate stamping cages, but with relatively low density, so the maximum speed is high. Common types are stamping and solid, and stamping types are more suitable for small and medium-sized bearings.

Advantages and characteristics: Not affected by commonly used bearing lubricants, including synthetic oils and greases: Excellent wear resistance, low noise, low friction coefficient when paired with rolling elements, and smooth operation. However, it should be noted that copper cages cannot be used in high temperature environments above 300°C, nor are they suitable for occasions such as ammonia that may cause seasonal breakage of brass. Steel cages:

3. Steel cages: Due to their high strength, good toughness, and easy processing, they are widely used in rolling bearings. Common materials include steel plates or steel forgings, and the types are stamping and solid. They are mostly used for deep groove ball bearings, spherical roller bearings and tapered roller bearings.

Advantages: Lightweight, high strength, unaffected by mineral oil-based or alkali-based lubricants, operating temperature up to 300*C, suitable for a variety of working environments. However, compared with copper cages, steel cages are slightly less wear-resistant and are prone to peeling and adhesion when rubbing against rolling elements, and may cause increased wear due to residual magnetism.

Product display

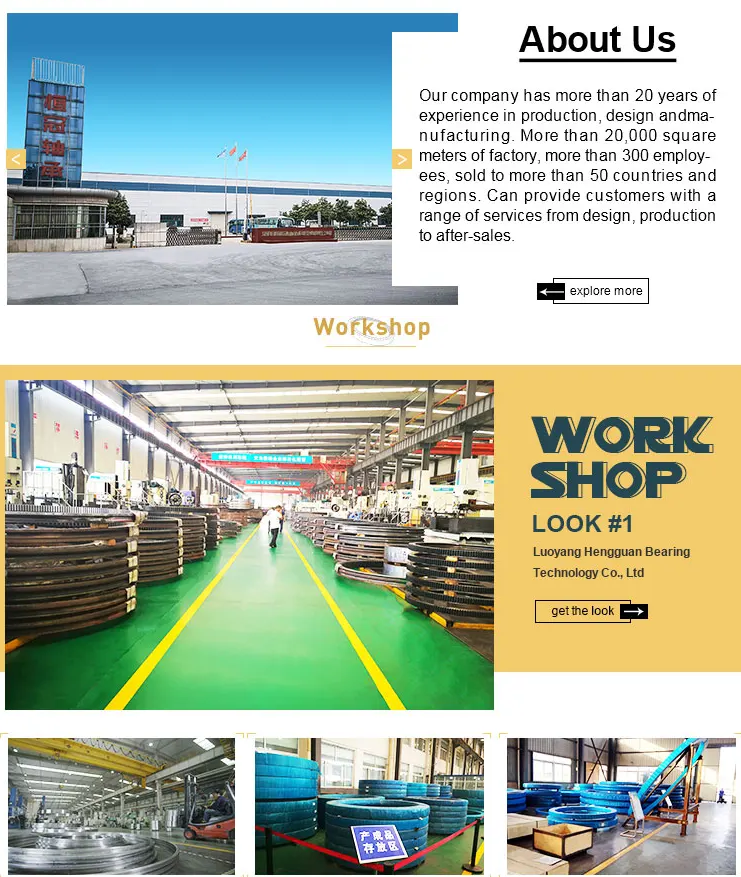

About Us

Application

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years' experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.