High Performance Slewing Bearing For Crane

- LYHGB

- Luoyang

- 45 days

- 4000 sets/month

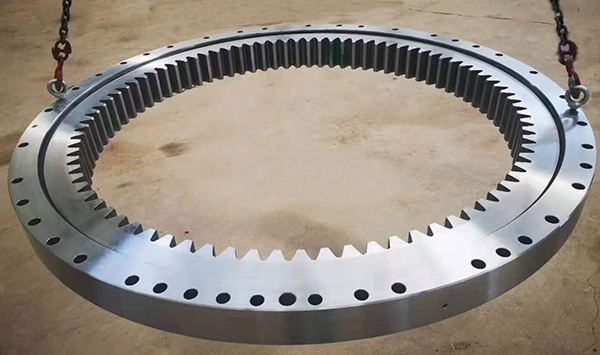

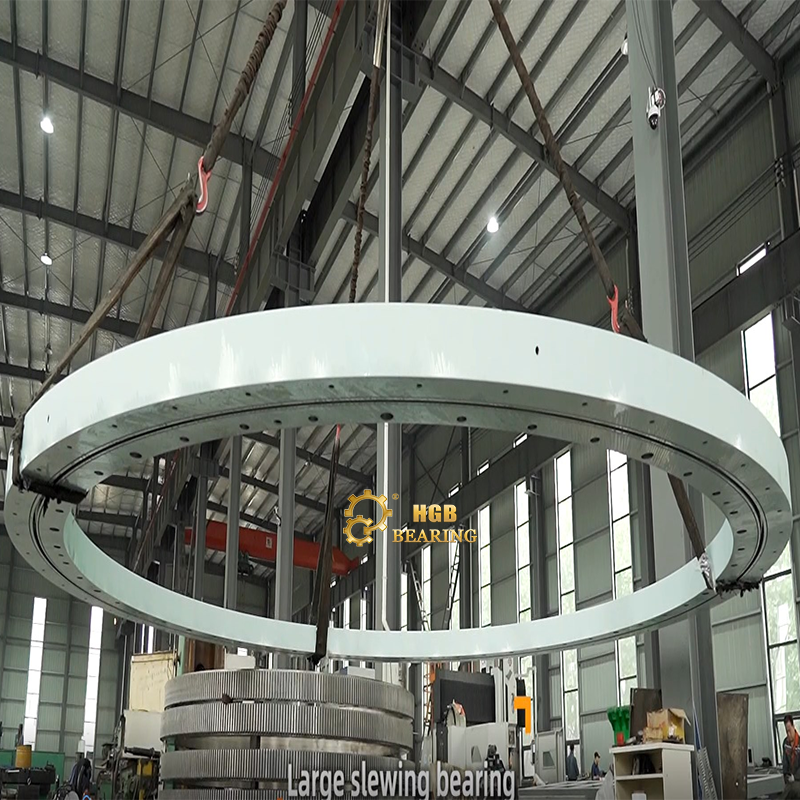

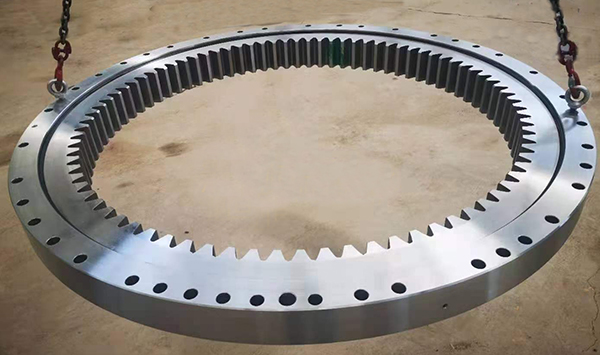

Slewing bearing is an important "joint" of the crane. Various loads and moments on the working device need to be transmitted to the chassis through the slewing bearing. Because the slewing bearing is overloaded, it is also the part where the crane is prone to failure, so it is necessary to install a new slewing bearing after long-term use. Truck cranes, crawler cranes and other heavy construction cranes are usually using large single row four-point contact ball slewing ring bearing. This type of slewing bearing can bear larger axial load, radial load and tilting moment, enabling crane to lift heavy loads stably and reliably.

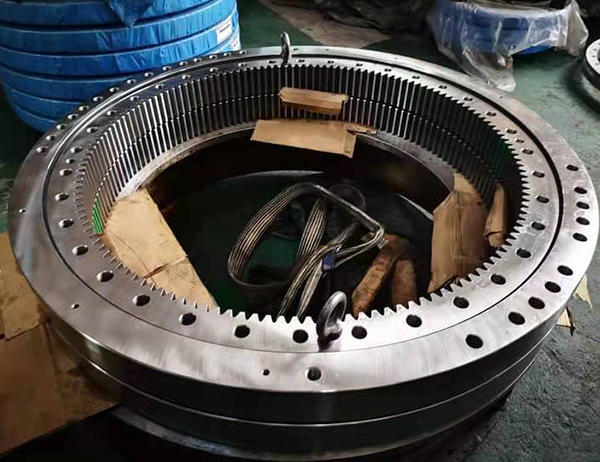

To improve the manufacturing accuracy and working life of the slewing bearing, we focus on the heat treatment process, raceway quenching to prevent quenching cracks on the surface of the raceway. For high precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings. So our slewing bearings are with features of high precision, long working life and durable to use.

High Performance Slewing Bearing For Crane with long working life

Slewing bearing is an important "joint" of the crane. Various loads and moments on the working device need to be transmitted to the chassis through the slewing bearing. Because the slewing bearing is overloaded, it is also the part where the crane is prone to failure, so it is necessary to install a new slewing bearing after long-term use. Truck cranes, crawler cranes and other heavy construction cranes are usually using large single row four-point contact ball slewing ring bearing. This type of slewing bearing can bear larger axial load, radial load and tilting moment, enabling crane to lift heavy loads stably and reliably.

To improve the manufacturing accuracy and working life of the slewing bearing, we focus on the heat treatment process, raceway quenching to prevent quenching cracks on the surface of the raceway. For high precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings. So our slewing bearings are with features of high precision, long working life and durable to use.

Popular models we make are as below

| KOTO NK450B-V |

| Roballo RK35H-3 |

| KOBELCO RK250-1 |

| KOBELCO RK250-2 |

| KOBELCO RK250-3 |

| KOBELCO PH450-3 |

| Grove TMS700B |

| Zoomlion QUY70 |

| Tadano TM-ZF503 |

.........

Welcome your inquiry. Or if you can measure the details or provide a drawing for other models, we can custom made for you.

Maintenance of crane slewing bearing

When carrying out maintenance work, first of all, pay attention to the danger of being dragged into the rotary pinion (Gear), and the danger of crushing and shearing. The working strength of the cantilever crane is light. The crane is composed of a column, a rotary arm rotary drive device and an electric hoist. The lower end of the column is fixed on the concrete foundation by anchor bolts, and the cantilever rotation is driven by a cycloidal pinwheel reduction device. The beam runs in a straight line from left to right and lifts heavy objects. The jib of the crane is a hollow steel structure, which is light in weight, large in span, large in lifting capacity, economical and durable. During inspection and maintenance, it is necessary to ensure that when starting the engine to perform the necessary slewing and luffing operations, any maintenance (wéi xiu) staff is not in the danger zone between the main boom, the loading car and the roller, or getting off the car and the roller. The danger zone in between, except for the crane operator (in the cab (indoor)).

Inspection of slewing bearing bolts (composition: head and screw)

1. Before each operation of the crane or at least once a week, visually inspect the bolts on the slewing bearing (composition: head and screw);

2. After 100 working hours of the first job of the slewing bearing, check whether the bolts (composition: head and screw) are loose, and check again at the 300th working hour; after that, check every 500 working hours; In this case, the inspection distance should be shortened.

3. The slewing bearing should be filled with lithium-based lubricating oil before installation;

4. When replacing bolts (composition: head and screw), "cleanse" the bolts, apply thread tightening glue, and then tighten them; use the crane according to the requirements of the operation manual and the crane energy table, Or check the tightening bolts regularly according to the requirements, you can avoid the danger of bolt fatigue damage. The cantilever crane is an industrial component and is a light-duty crane. It consists of a column, a slewing arm slewing drive device and an electric hoist. It has light weight, large span, large lifting capacity, economical and durable.

Routine Inspection of Slewing Bearings

1. Check the flexibility of the rotation on schedule; if noise (dB) or impact is found, it should be stopped immediately for inspection, troubleshooting, and dismantling if necessary;

2. Regularly inspect whether the rotating ring gear is cracked or damaged, and whether the meshing tooth surface has occlusion, gnawing, tooth surface peeling, etc.;

3. Check the condition of the seal on time. If the seal is found to be damaged, it should be replaced in time. If it is found to be dropped, it should be reset in time. The tooth surface of lubriCATion slewing bearing ring gear has been coated with anti-rust oil before leaving the factory. The validity period of this anti-rust is generally 3 to 6 months. After the validity period is exceeded, anti-rust oil should be applied in time.

Lubricate the raceway of the slewing bearing

The raceway must be filled with lubriCATion grease on schedule according to the working environment. After 50 working hours for the first time, the raceway should be filled with lubricating oil (LubriCATing oil), and then every 300 working hours after that. The slewing bearing must be filled with grease before and after being placed for a long time. If steam jet cleaners or stationary water jets are used to clean the crane, care must be taken to ensure that water does not penetrate (Osmosis) the slewing ring connections, and then the slewing ring connections must be lubricated.

Filling the grease should be carried out with the slewing bearing rolling slowly. When the lubriCATion grease overflows from the seal, it indicates that the filling is completed. The overflowing grease will form a film and act as a seal.