Single Row Four Point Contact Ball Slewing Bearing( 01 Series)

- LYHGB

- Luoyang

- 40 days

- 4000 sets/ month

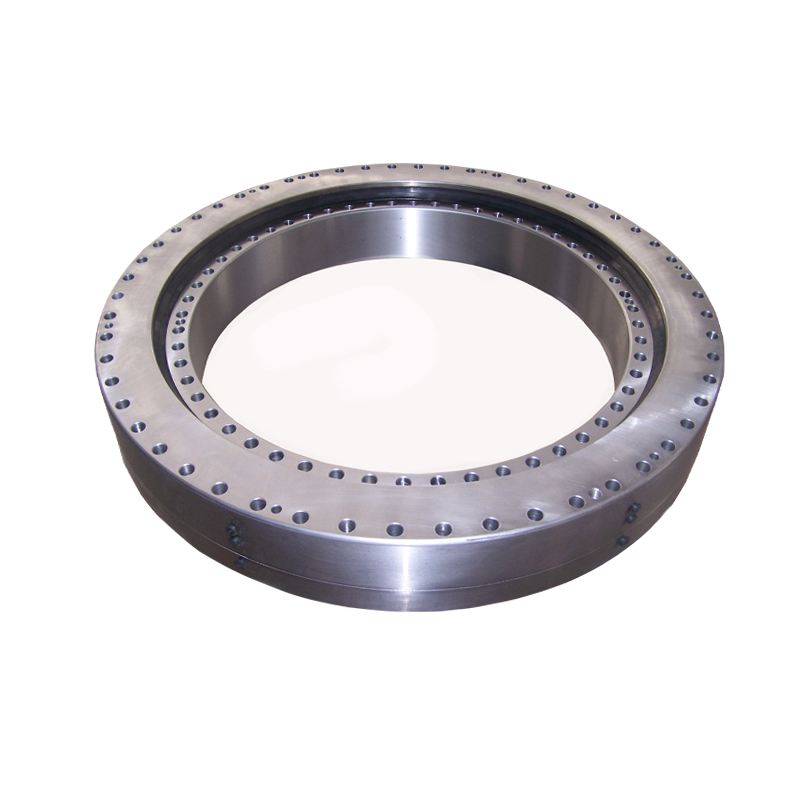

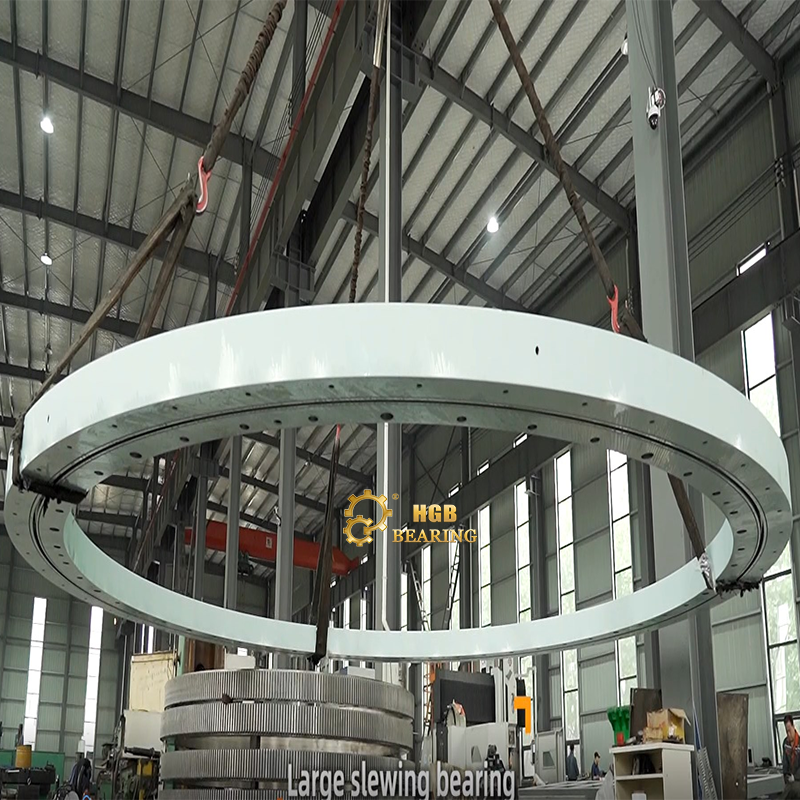

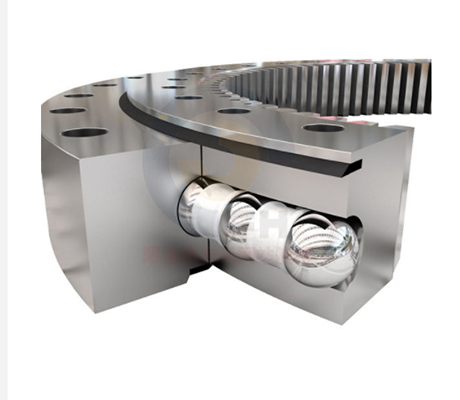

Single row four point contact ball slewing bearing 01 series is a standard model series in China. It is made of two seat rings. The balls and the raceway are with four points contact, via which the axial force, radial force and resultant moment is born simultaneously. Outer Diameter is from 280mm to 4726mm. Most models slewing ring are with ready stock or semi-finished material stock, which can deliver out within 15 days.

Standard material we adopt is 50Mn and 42CrMo. Other customized material is also acceptable. We support models selection based on your application; teeth quenching and grinding; customized surface treatment like Blackening, phosphating, galvanizing, sandblasting and etc.

In the production process of slewing ring bearing, whole process inspection is implemented strictly to ensure that each set of products are qualified. For high-precision products, precise grinding is used to effectively control the parameters of ring ellipse, wall thickness and flatness, so as to ensure that the precision of finished products meets the requirements of standards or customer drawings.

This series models are with advantage of compact design, flexible rotating and light weight. It is widely used on rotary conveyor, welding arm and positioner, light/medium duty cranes, excavators and other engineering machines. Please feel free to tell us the application you use and we can help you choose the proper model and offer you a professional solution as soon as possible.

Single Row Four Point Contact Ball Slewing Bearing( 01 Series)

The single row four-point contact ball slewing bearing is made of two seat rings. It is with compact structure, light weight, and four-point contact between steel ball and arc raceway. It can bear axial force, radial force and overturning moment at the same time. It is widely used on rotary conveyor, welding arm and positioner, light/medium duty cranes, excavators and other engineering machines.

Slewing bearing Material

Support ring: 50Mn, 42CrMo,or customized

Steel balL:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Material

Cage: include integral cage, segment cage and spacer-type cage. 20# steel or copper for integral and segment cages, PA 1010 resin or QA110-3-105 albronze for spacer-type cages.

Seals:uses NBR or VITON, few felted wool.

Equipment

Wide production workshop and strong production team as a support,ensure the products can be produced by required quality and quantity. andThereby increase the customer benefits.

Below is our production equipment with advanced technology , the stable and longevity bearing produce from these equipment .

1.6m vertical CNC 6.3m CNC vertical lathe 8m quench machining 6m magnetic detection

grinding machine tool machine

1.6m CNC vertical lathe 2.5m vertical CNC 3.5m CNC gear shaping 3.5m CNC vertical lathe

grinding machine machine

4 meter high speed 4m vertical CNC grinding 4m CNC hardening 5m CNC grantry drilling

CNC milling machine machine machine machine

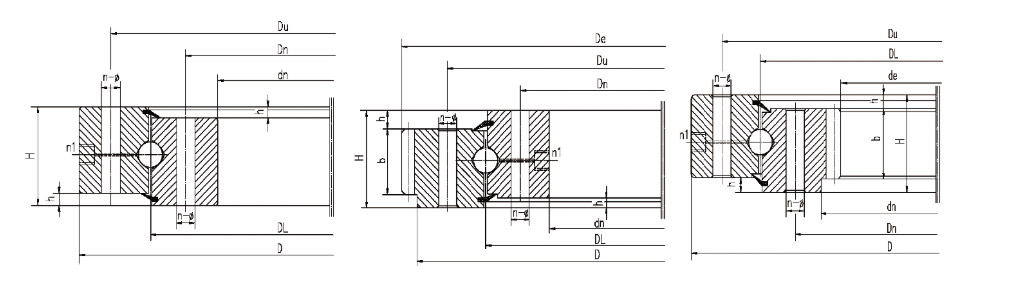

Technical Parameters

| Bearing type | Boundary dimensions | Mounting hole diameter | Structure dimensions | Gear parameters | Mass KG | |||||||||||||||

| Non-gear type | External gear type | Internal gear type | D | dn | H | Du | Dn | n | φ | DL | h | n1 | m | Ext gear | Int gear | b | x | |||

| mm | mm | mm | mm | De | Z | de | Z | mm | ||||||||||||

| 010.30.500.** | 011.30.500.** | 013.30.500.** | 602 | 398 | 80 | 566 | 434 | 20 | 18 | 500 | 10 | 4/M10*1 | 5 | 630 | 123 | 365 | 74 | 60 | +0.5 | 75.8 |

| 012.30.500.** | 014.30.500.** | 6 | 630 | 102 | 366 | 62 | 60 | +0.5 | 75.8 | |||||||||||

| 010.30.560.** | 011.30.560.** | 013.30.560.** | 662 | 458 | 80 | 626 | 494 | 20 | 18 | 560 | 10 | 4/M10*1 | 5 | 690 | 135 | 425 | 86 | 60 | +0.5 | 94 |

| 012.30.560.** | 014.30.560.** | 6 | 690 | 112 | 426 | 72 | 60 | +0.5 | 94 | |||||||||||

| 010.30.630.** | 011.30.630.** | 013.30.630.** | 732 | 528 | 80 | 696 | 564 | 24 | 18 | 630 | 10 | 4/M10*1 | 6 | 774 | 126 | 492 | 83 | 60 | +0.5 | 110 |

| 012.30.630.** | 014.30.630.** | 8 | 776 | 94 | 488 | 62 | 60 | +0.5 | 110 | |||||||||||

| 010.30.710.** | 011.30.710.** | 013.30.710.** | 812 | 608 | 80 | 776 | 644 | 24 | 18 | 710 | 10 | 4/M10*1 | 6 | 852 | 139 | 570 | 96 | 60 | +0.5 | 120 |

| 012.30.710.** | 014.30.710.** | 8 | 856 | 104 | 568 | 72 | 60 | +0.5 | 120 | |||||||||||

| 010.40.800.** | 011.40.800.** | 013.40.800.** | 922 | 678 | 100 | 878 | 722 | 30 | 22 | 800 | 10 | 6/M10*1 | 8 | 968 | 118 | 632 | 80 | 80 | +0.5 | 256 |

| 012.40.800.** | 014.40.800.** | 10 | 970 | 94 | 630 | 64 | 80 | +0.5 | 256 | |||||||||||

| 010.40.900.** | 011.40.900.** | 013.40.900.** | 1022 | 778 | 100 | 978 | 822 | 30 | 22 | 900 | 10 | 6/M10*1 | 8 | 1064 | 130 | 736 | 93 | 80 | +0.5 | 240 |

| 012.40.900.** | 014.40.900.** | 10 | 1070 | 104 | 730 | 74 | 80 | +0.5 | 240 | |||||||||||

| 010.40.1000.** | 011.40.1000.** | 013.40.1000.** | 1122 | 878 | 100 | 1078 | 922 | 36 | 22 | 1000 | 10 | 6/M10*1 | 10 | 1190 | 116 | 820 | 83 | 80 | +0.5 | 270 |

| 012.40.1000.** | 014.40.1000.** | 12 | 1188 | 96 | 816 | 69 | 80 | +0.5 | 270 | |||||||||||

| 010.40.1120.** | 011.40.1120.** | 013.40.1120.** | 1242 | 998 | 100 | 1198 | 1042 | 36 | 22 | 1120 | 10 | 6/M10*1 | 10 | 1300 | 127 | 940 | 95 | 80 | +0.5 | 300 |

| 012.40.1120.** | 014.40.1120.** | 12 | 1308 | 106 | 936 | 79 | 80 | +0.5 | 300 | |||||||||||

| 010.45.1250.** | 011.45.1250.** | 013.45.1250.** | 1390 | 1110 | 110 | 1337 | 1163 | 40 | 26 | 1250 | 10 | 6/M10*1 | 12 | 1452 | 118 | 1044 | 88 | 90 | +0.5 | 420 |

| 012.45.1250.** | 014.45.1250.** | 14 | 1456 | 101 | 1036 | 75 | 90 | +0.5 | 420 | |||||||||||

| 010.45.1400.** | 011.45.1400.** | 013.45.1400.** | 1540 | 1260 | 110 | 1487 | 1313 | 40 | 26 | 1400 | 10 | 6/M10*1 | 12 | 1608 | 131 | 1188 | 100 | 90 | +0.5 | 480 |

| 012.45.1400.** | 014.45.1400.** | 14 | 1610 | 112 | 1190 | 86 | 90 | +0.5 | 480 | |||||||||||

| 010.45.1600.** | 011.45.1600.** | 013.45.1800.** | 1740 | 1460 | 110 | 1687 | 1513 | 45 | 26 | 1600 | 10 | 8/M10*1 | 14 | 1820 | 127 | 1386 | 100 | 90 | +0.5 | 550 |

| 012.45.1600.** | 014.45.1800.** | 16 | 1824 | 111 | 1376 | 87 | 90 | +0.5 | 550 | |||||||||||

| 010.45.1800.** | 011.45.1800.** | 013.45.1800.** | 1940 | 1660 | 110 | 1887 | 1713 | 45 | 26 | 1800 | 10 | 8/M10*1 | 14 | 2016 | 141 | 1568 | 113 | 90 | +0.5 | 610 |

| 012.45.1800.** | 014.45.1800.** | 16 | 2016 | 123 | 1568 | 99 | 90 | +0.5 | 610 | |||||||||||

| 010.60.2000.** | 011.60.2000.** | 013.60.2000.** | 2178 | 1825 | 144 | 2110 | 1891 | 48 | 33 | 2000 | 12 | 8/M10*1 | 16 | 2272 | 139 | 1728 | 109 | 120 | +0.5 | 1100 |

| 012.60.2000.** | 014.60.2000.** | 18 | 2268 | 123 | 1728 | 97 | 120 | +0.5 | 1100 | |||||||||||

| 010.60.2240.** | 011.60.2240.** | 013.60.2240.** | 2418 | 2065 | 144 | 2350 | 2131 | 48 | 33 | 2240 | 12 | 8/M10*1 | 16 | 2496 | 153 | 1984 | 125 | 120 | +0.5 | 1250 |

| 012.60.2240.** | 014.60.2240.** | 18 | 2502 | 136 | 1980 | 111 | 120 | +0.5 | 1250 | |||||||||||

| 010.60.2500.** | 011.60.2500.** | 013.60.2500.** | 2678 | 2325 | 144 | 2610 | 2391 | 56 | 33 | 2500 | 12 | 8/M10*1 | 18 | 2772 | 151 | 2232 | 125 | 120 | +0.5 | 1400 |

| 012.60.2500.** | 014.60.2500.** | 20 | 2780 | 136 | 2220 | 112 | 120 | +0.5 | 1400 | |||||||||||

| 010.60.2800.** | 011.60.2800.** | 013.60.2800.** | 2978 | 2625 | 144 | 2910 | 2691 | 56 | 33 | 2800 | 12 | 8/M10*1 | 18 | 3078 | 168 | 2520 | 141 | 120 | +0.5 | 1600 |

| 012.60.2800.** | 014.60.2800.** | 20 | 3080 | 151 | 2520 | 127 | 120 | +0.5 | 1600 | |||||||||||

| 010.75.3150.** | 011.75.3150.** | 013.75.3150.** | 3376 | 2922 | 174 | 3286 | 3014 | 56 | 45 | 3150 | 12 | 8/M10*1 | 20 | 3480 | 171 | 2820 | 142 | 150 | +0.5 | 2800 |

| 012.75.3150.** | 014.75.3150.** | 22 | 3476 | 115 | 2816 | 129 | 150 | +0.5 | 2800 | |||||||||||

| 010.75.3550.** | 011.75.3550.** | 013.75.3550.** | 3376 | 3322 | 174 | 3686 | 3414 | 56 | 45 | 3550 | 12 | 8/M10*1 | 20 | 3880 | 191 | 3220 | 162 | 150 | +0.5 | 3200 |

| 012.75.3550.** | 014.75.3550.** | 22 | 3894 | 174 | 3212 | 147 | 150 | +0.5 | 3200 | |||||||||||

| 010.75.4000.** | 011.75.4000.** | 013.75.4000.** | 4226 | 3772 | 174 | 4136 | 3864 | 60 | 45 | 4000 | 12 | 10/M10*1 | 22 | 4334 | 194 | 3652 | 167 | 150 | +0.5 | 3600 |

| 012.75.4000.** | 014.75.4000.** | 25 | 4350 | 171 | 3650 | 147 | 150 | +0.5 | 3600 | |||||||||||

| 010.75.4500.** | 011.75.4500.** | 013.75.4500.** | 4726 | 4272 | 174 | 4636 | 4364 | 60 | 45 | 4500 | 12 | 10/M10*1 | 22 | 4840 | 271 | 4158 | 190 | 150 | +0.5 | 4000 |

| 012.75.4500.** | 014.75.4500.** | 25 | 4850 | 191 | 1450 | 167 | 150 | +0.5 | 4000 | |||||||||||

We are a professional bearings manufacturer with strong research and innovation capabilities....more