Large non-standard internal ring gear manufacturer

- LYHGB

- LUOYANG

- 45 DAYS

- 4000 SETS/ MONTH

The main function of the inner gear ring in large mechanical parts is to convey and transmit. With its advantages of high precision, high strength and easy installation and maintenance, it plays an important role in various mechanical transmission systems.

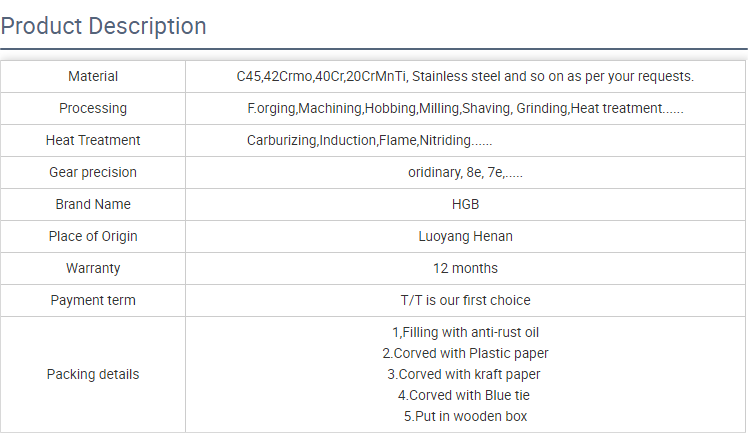

Product detial

As an important part of large mechanical parts, the internal gear ring has a complex and delicate structural design. Its large outer diameter and thin rim require high-precision manufacturing technology to ensure stable performance. The product undergoes strict quality control to ensure excellent performance in various working environments.

Advantages and characteristics:

1. High precision: The use of advanced manufacturing processes and technologies ensures that the internal gear ring has extremely high rotation accuracy and meets the needs of high-precision transmission.

2. High strength: Select high-quality materials. After precision forging and heat treatment, the internal gear ring has excellent strength and wear resistance, extending its service life.

3. Easy to install and maintain: Reasonable design, easy installation, and low maintenance cost, which improves the reliability and economy of the equipment.

The processing technology of the internal gear ring includes steps such as forging preliminary forming, polishing, rough and fine processing, soft nitriding, and shot blasting anti-rust treatment. These processes ensure the high precision and high quality of the internal gear ring. At the same time, in order to address the problem that extra-large precision gear rings used in large CNC equipment are easy to deform and difficult to process, advanced process manufacturing technologies need to be adopted, such as heat treatment and cutting processes, workpiece flipping and anti-deformation processes, etc., to improve manufacturing accuracy and efficiency.

Product display

About US

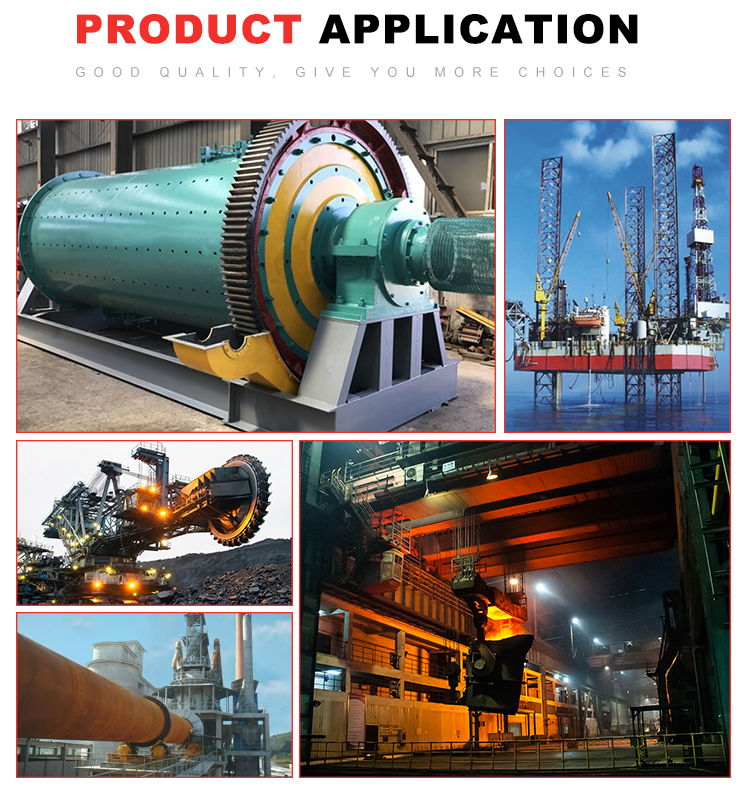

Application

FAQ

1.Q: Are you trading company or manufacturer ?

A: We are professional manufacturer with 20 years' experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.