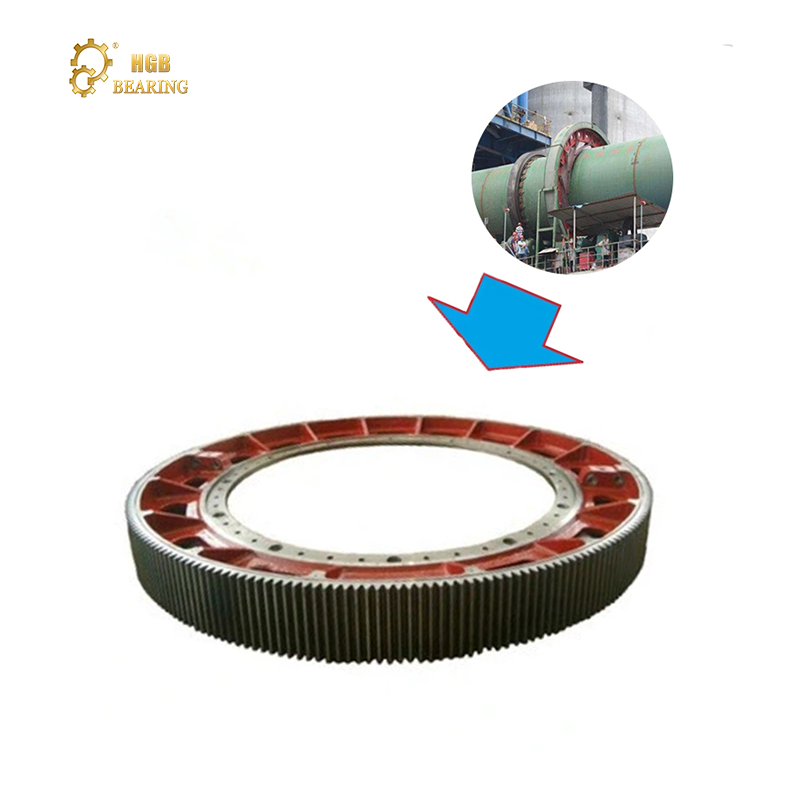

Ring Gear

Ring gear, Gear wheel or Girth gear is a part used in mechanical transmission. Material is usually forged or casting alloy steel with surface carburizing or hardening treatment. The gear has the high bearing capacity and durability in practical application, which is widely used in high speed and heavy load machinery because of its stable transmission, low impact, vibration and noise.

-

Drying machine large gear ring

In dryers and dryers, the role of the large gear ring is crucial, usually used to transmit power and support rotating components. Through reasonable material selection, design, and maintenance, the stable and reliable performance of the large gear ring can be ensured, providing strong support for the long-term operation of the equipment.

Email Details

The large gear ring transmits the power of the motor to the rotating parts of the equipment through meshing with the small gear, thereby driving the operation of the equipment. The large gear ring is generally made of high-strength materials, such as cast steel or alloy steel, to ensure that it can withstand the strong forces and high temperatures generated during equipment operation. The accuracy and wear resistance of the large gear ring directly affect the service life and efficiency of the equipment. -

Customizable large spur gears high quality ring gear and pinion gear wheel supplier

1.A spur gear is a simple gear with parallel teeth and a gear axis. It is used to transmit power between parallel shafts. Spur gears are primarily used to reduce speed and increase torque. Spur gears have the advantages of simple design, easy manufacturing, low cost, high efficiency, and can achieve various transmission ratios, but the disadvantage is that they are noisy.

Email Details

Helical gears have teeth that are inclined to the axis of the gear. For the same tooth width, helical gears have longer teeth than spur gears. Therefore, more power can be transferred between parallel shafts than with spur gears. The advantages of helical gears are higher load carrying capacity and contact ratio compared to spur gears. Smoother and quieter than spur gears. and have good accuracy levels. The disadvantage of helical gears is that they are less efficient compared to spur gears. The helix angle also increases the axial thrust on the shaft.

2.Our company can produce different type pinion gears such as spur gear, helical gear, worm gear according to the customer's drawing and requirements. Our product is highly appreciated amongst customers for its dimensional accuracy, excellent strength and high performance. Teeth quenching, teeth grinding and surface treatment like oxide, nitriding, sandblasting are also available. -

Factory can customize spur or helical or herringbone gears according to customer needs

1.Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear and shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries.

Email Details

2.A spur gear is a simple gear with parallel teeth and a gear axis. It is used to transmit power between parallel shafts. Spur gears are primarily used to reduce speed and increase torque. They are also used at high speeds in some consumer products. The following are the applications of spur gears in several products: mixers, washing machines, automobiles, bicycles, mechanical clocks, etc.

Helical gears have teeth that are inclined to the axis of the gear. For the same tooth width, helical gears have longer teeth than spur gears. Therefore, they can transmit more power between parallel shafts than spur gears.

Helical gears are used to transmit heavy loads between parallel shafts at very high rotational speeds. The following are the applications of helical gears in various products. Automotive gearboxes, printing and other machinery, conveyors and elevators, factory automation, etc.

Double helical gears have opposing helical teeth with grooves between them. Herringbone gears, on the other hand, have no grooves. Both gear types are used to transmit power between parallel shafts. Compared with helical gears, herringbone gears and double helical gears have the advantage of balancing bidirectional axial thrust. Therefore, they are used in applications with high load-carrying capacity requirements, such as differentials and heavy machinery. -

Professional technical factory Non standard custom herringbone gear manufacturer

1.A herringbone gear, a special type of double helical gear, is a special type of gear that is a side-by-side (not face-to-face) combination of two helical gears in opposite directions. Viewed from the top, each of the gear's spiral grooves looks like the letter V, and many of the spiral grooves together form a herringbone pattern. Unlike helical gears, herringbone gears do not create additional axial loads.

Email Details

Like helical gears, they have the advantage of delivering power smoothly because more than two teeth are in mesh at any one time. Their advantage over helical gears is that half of the side thrust is balanced by the other half of the side thrust. This means that herringbone gears can be used in torque gearboxes without the need for extensive thrust bearings. The herringbone gear was therefore an important step in the introduction of steam turbines for ship propulsion.

Precision herringbone gears are more difficult to manufacture and therefore more expensive than equivalent spur or helical gears, so they are often used in heavy machinery.

2.Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries. -

Customized double helical gears herringbone from professional manufacturers

1.A combination of left and right helical gears with the same helix angle is called a double helical gear, which transmits rotational motion between parallel axes.

Email Details

2.Double helical gears and herringbone gears are the same type of gear, but those with grooves between the left and right helical teeth are called double helical gears, those without grooves -

Factory specialized customization of bevel gears

1.Bevel gears are used to transmit motion and power between two intersecting axes. In general machinery, the intersection angle between the two axes of bevel gears is equal to 90° (but it may not be equal to 90°). Similar to cylindrical gears, bevel gears have indexing cones, tip cones, root cones and base cones. The cone has a big end and a small end, and the circles corresponding to the big end are called the graduation circle (its radius is r), the tooth tip circle, the tooth root circle and the base circle. The movement of a pair of bevel gears is equivalent to pure rolling of a pair of pitch cones.

Email Details

2.Our company has many years of manufacturing and production experience, complete equipment, and a professional technical team. We have cooperated with many new and old customers at home and abroad for many times. We can design and produce according to the required drawings provided by customers to meet customer needs. We also have a pair of First-class service, please believe us. If you have needs, you can find out first. Customers are welcome to consult. -

Customizable segmented large gear ring ball mill manufacturer

1.Segmented large ring gears are used to drive large rotating systems, such as dryers, rotary kilns, and horizontal mills

Email Details

2.Advantages

(1) Minimum vibration: The segmented large ring gear has high-precision pitch.

(2)Easy to replace because the large ring gear is divided into multiple segments without having to disassemble the entire ring gear.

(3)The longer service life is due to the use of appropriate size and reasonable lubrication, so that the large ring gear made of material has no wear in actual use. -

Factory direct sales prices can be customized for herringbone helical gear large gear rings

1.Herringbone gears combine the advantages of helical gears (high load capacity) and spur gears (no axial force).

Email Details

2.Herringbone gears can transmit high torque due to their relatively long tooth length (due to the inclination). However, the complex and therefore expensive production of this gear type is limited to special applications. (e.g. for large transfers) -

Excellent team factory with high quality rotary kiln large girth gear ring

Large ring gear is fully tempered and quenched , so that it has good comprehensive mechanical properties, and has good plasticity and toughness while ensuring high strength. To provide customers with ring gear castings with high service life and high operating rate.

Email Details