large gear

-

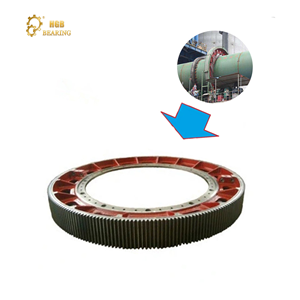

Drying machine large gear ring

In dryers and dryers, the role of the large gear ring is crucial, usually used to transmit power and support rotating components. Through reasonable material selection, design, and maintenance, the stable and reliable performance of the large gear ring can be ensured, providing strong support for the long-term operation of the equipment. The large gear ring transmits the power of the motor to the rotating parts of the equipment through meshing with the small gear, thereby driving the operation of the equipment. The large gear ring is generally made of high-strength materials, such as cast steel or alloy steel, to ensure that it can withstand the strong forces and high temperatures generated during equipment operation. The accuracy and wear resistance of the large gear ring directly affect the service life and efficiency of the equipment.

large gear ring customized large gear ring girth gear Non standard customized product solution providerEmail Details -

Factory can customize spur or helical or herringbone gears according to customer needs

1.Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear and shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries. 2.A spur gear is a simple gear with parallel teeth and a gear axis. It is used to transmit power between parallel shafts. Spur gears are primarily used to reduce speed and increase torque. They are also used at high speeds in some consumer products. The following are the applications of spur gears in several products: mixers, washing machines, automobiles, bicycles, mechanical clocks, etc. Helical gears have teeth that are inclined to the axis of the gear. For the same tooth width, helical gears have longer teeth than spur gears. Therefore, they can transmit more power between parallel shafts than spur gears. Helical gears are used to transmit heavy loads between parallel shafts at very high rotational speeds. The following are the applications of helical gears in various products. Automotive gearboxes, printing and other machinery, conveyors and elevators, factory automation, etc. Double helical gears have opposing helical teeth with grooves between them. Herringbone gears, on the other hand, have no grooves. Both gear types are used to transmit power between parallel shafts. Compared with helical gears, herringbone gears and double helical gears have the advantage of balancing bidirectional axial thrust. Therefore, they are used in applications with high load-carrying capacity requirements, such as differentials and heavy machinery.

Email Details -

Professional technical factory Non standard custom herringbone gear manufacturer

1.A herringbone gear, a special type of double helical gear, is a special type of gear that is a side-by-side (not face-to-face) combination of two helical gears in opposite directions. Viewed from the top, each of the gear's spiral grooves looks like the letter V, and many of the spiral grooves together form a herringbone pattern. Unlike helical gears, herringbone gears do not create additional axial loads. Like helical gears, they have the advantage of delivering power smoothly because more than two teeth are in mesh at any one time. Their advantage over helical gears is that half of the side thrust is balanced by the other half of the side thrust. This means that herringbone gears can be used in torque gearboxes without the need for extensive thrust bearings. The herringbone gear was therefore an important step in the introduction of steam turbines for ship propulsion. Precision herringbone gears are more difficult to manufacture and therefore more expensive than equivalent spur or helical gears, so they are often used in heavy machinery. 2.Our company mainly produces non-standard mechanical products such as rotary bearings, gear rings, and shafts, which can be customized according to customer requirements. Gear shafts can produce structures such as straight teeth, helical teeth, and herringbone teeth. Rotary bearings have external teeth, internal teeth, and no teeth. We have cooperated with many new and old customers both domestically and internationally,The factory is fully equipped with professional workers and technical teams, and a complete sales team provides one-on-one service in terms of service. and we believe we welcome inquiries.

Email Details -

Customizable segmented large gear ring ball mill manufacturer

1.Segmented large ring gears are used to drive large rotating systems, such as dryers, rotary kilns, and horizontal mills 2.Advantages (1) Minimum vibration: The segmented large ring gear has high-precision pitch. (2)Easy to replace because the large ring gear is divided into multiple segments without having to disassemble the entire ring gear. (3)The longer service life is due to the use of appropriate size and reasonable lubrication, so that the large ring gear made of material has no wear in actual use.

Email Details -

Customizable factory production and sales of ball mill large gear rings

1.The large ring gear is one of the important components of rotary kiln, ball mill, dryer and other machinery, so the quality of the ring gear is related to the stability and service life of the ball mill and rotary kiln. 2.The large ring gear is a very critical component in the transmission device of ball mills and rotary kilns. It drives the entire cylinder to rotate at low speed for a long time. Its quality directly affects the smoothness of the transmission system of ball mills and rotary kilns, the stability of operation, and the quality of the lining. The service life and the operation rate of the kiln and the grinding mill, so the quality requirements of the large ring gear in actual production are very high.

Email Details -

OEM High Precision quality custom Main Shaft Rotor Shaft gear

The gear shaft is an important component in mechanical transmission. It transmits power and energy through the meshing of gears. torque. The gear shaft is the shaft on which the gear is installed. Its main function is to support the gear and connect the gear to the The rotational force is transmitted. The gear shaft is usually made of a long strip of metal material. Has certain strength and stiffness. The end of the gear shaft is connected to the driving device (such as a motor), The other end is connected to the driven device (such as mechanical equipment). When the drive unit rotates, by Due to the meshing effect of the gears, the rotational force of the driving wheel and the driven wheel will be transmitted along the gear shaft.

Email Details -

Machining Forged Large Pinion Shaft High Quality Alloy Steel Large Module Gear Shaft

Slewing bearing ring shaft forgings are produced and processed by Luoyang Heng guan Bearing according to customer requirements.They are mainly used in modules,power plants,buildings,and locomotive.They have the same strength,light weight,high productivity,high flexibility,low raw material consumption,and high cost performance.Slewing shaft forgings can be used in slewing ring shaft bearing processing,medical equipment,aviation forging,and automobile industry.At present,the products sincerely welcome overseas customer to inquire and negotiate.

Oem Precision Forging shaft Large Module Gear Shaft Custom Forged Large Gear Shaft Forged Large Pinion ShaftEmail Details -

Hot

Customized Large Diameter Transmission Part Teeth Grinding Spur Gear Wheel

Select high quality 35CrMo, 42CrMo, C45 steel material, and alloy steel according to customer's requirements. Full production line for processing and can provide one to one customization service to customers. Support teeth quenching, teeth grinding, surface treatment like Carburizing,Nitriding etc. Good at high precision ring gears processing with professional inspection teams. Teeth precision 2, 3, 5, 7, 8 grade can be acheived perfectly.

Email Details